Kitchen Risk Assessments for Cafe and Restaurant

Health and safety are important aspects of any workplace. Working in a kitchen environment has its own unique health and safety. Therefore, each kitchen should conduct a risk assessment test to determine what reasonable steps can be taken to eliminate the potential hazard and ensure the safety of management, kitchen staff, and customers. Here’s a step by step guide on conducting a kitchen safety risk assessment and the areas you need to cover.

Who Should Conduct the Kitchen Risk Assessment?

The employer is responsible for ensuring that the kitchen risk assessment is complete. This can be done by any competent person in the business with sufficient experience, skills, training, and knowledge to carry out the procedures safely. The owner of the business, general manager, head chef, and kitchen manager can be considered among those qualified for the job.

Steps of a Kitchen Risk Assessment

Regardless of whether the risk assessment is for a school cafeteria, or a restaurant kitchen, or other catering businesses, all risk assessments are conducted in more or less the same manner, by following the steps mentioned below in the exact same order. When you write yours make sure you analyse the potential risks in your kitchen and categorise them in the exact same order.

Step One: Identifying the Types of Hazard

The first step begins with the initiation of a thought process. Start by walking around the kitchen and identifying potential hazards. When you are familiar with your workspace, it can be easy for you to overlook the risks. Check the accident book to see if there is a chance for previously occurred accidents to happen again. Ask your employees for their input, listen to their concerns and opinions, and ask them about their past experiences. Create a gist of all the possible risks such as ‘slips and trips,’ ‘fire explosions,’ ‘injury caused by manual handling of heavy objects’, etc.

For this article, we will be using one example of a potential kitchen hazard and elaborate it further in each step as we progress. Let’s consider the risk of injuries caused by manually lifting heavy objects. Your staff may be strong enough to lift such objects however injuries can affect anyone and often they come unannounced. The existence of heavy material at your workplace should be the signal for you to identify the hazard.

Step Two: Decide Who Might be Harmed and How

For each hazard you identify, you have to be clear about who might be harmed—this will help you identify ways to control the risk. Think about specific job roles; for example, the line cooks are usually vulnerable to injuries from cutting, slicing, and sawing. Also, think about the use of specific equipment and the people who will be affected if they happen to use a faulty piece of equipment. For example, the entire kitchen staff may suffer from an explosion hazards in the case of a gas leak.

As for injuries caused by manually lifting heavy objects, young people, those who haven’t been in training for a sufficient amount of time, or those lacking strength are likely to suffer from injuries to their soft tissues such as the neck, back, and shoulders.

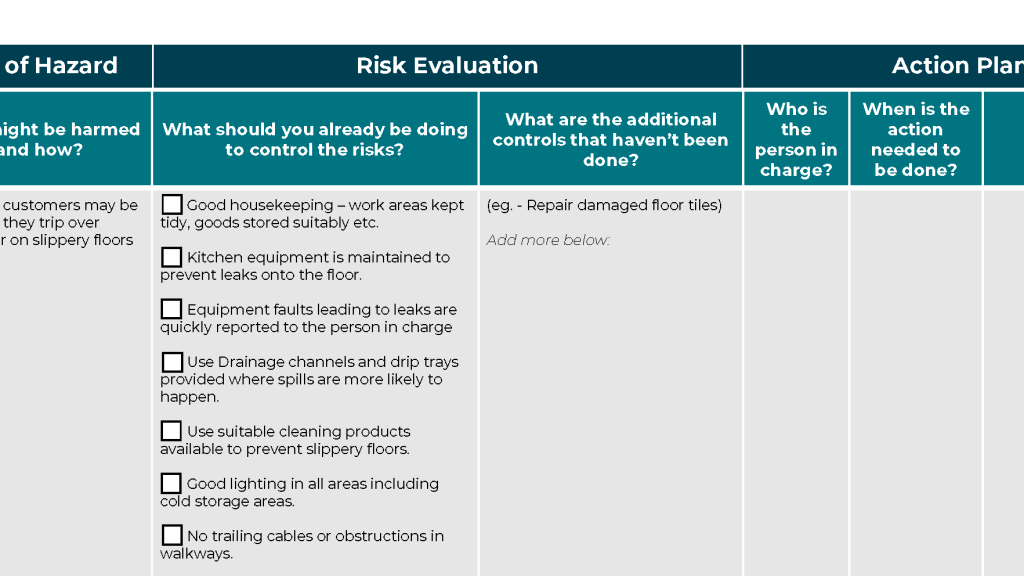

Step Three: Evaluate the Risks and What You Should be Doing to Control the Risks

Now that you have a good understanding of the hazards and who might be affected, you need to think about how likely it is that harm will occur, what steps you can take to reduce that risk. You must try your level best to remove all the severe risks you’ve managed to spot and reduce all the mild to moderate risks to the maximum possible extent.

Answer the following questions:

1) What are you already doing to control the risk/hazard?

2) Is there anything else you can be doing to control the risk?

You might find there are some basic steps you can take to control the risk or that you might already have some control measures in place. For example, in order to limit injuries resulting from lifting heavy objects you can ensure that supplies are bought in smaller packages or that they are stored at the waist level so that workers can pick them up without any hassle.

Step Four: Record Any Additional Controls If Needed

After you’ve created a list of the controls you already have in place, you should look at each hazard and record where your existing controls are not good enough. Then, note down what additional measures you can take to keep your staff safe and sound in the kitchen. For example, if slippery floors make those working in the kitchen more prone to trips and falls, perhaps you should avoid using products with too much wax or oil.

To reduce injuries caused by lifting heavy objects, you can use additional mechanical or lifting aids for bulky items, especially those placed on the ground or the shoulder level.

Step Five: The Importance of the Decide the Person-In-Charge

By assigning a person certain responsibilities, you can take note of their accountability and better ensure that all the measures are properly implemented. Should anything seem out of place, you can inquire the person in charge about the reasons for it. Make sure your choice represents someone whose role necessitates them to look over the safety of the kitchen. Usually, it is the manager or the kitchen staff who are assigned the role of assessing the risks of working in the kitchen.

Step Six: Set a Deadline for the Action

For the controls to be properly implemented, you need to make sure that they are practiced regularly. Therefore, you should note how frequently and when the actions mentioned in steps 2 and 3 should be enforced. By doing this, you can get a rough idea of how often to update the risk assessment sheet. For example, to prevent slips and trips, you should regularly use anti-slip cleaners on a daily basis, if not at least once every 2-3 days.

Step Seven: Jot Down the Additional Remarks

Use this section to place any comments or reminders for yourself or the staff. In addition, if a seemingly important piece of information about any of the hazards you recorded does not fit into the categories (or steps) mentioned above, you can jot it down in the ‘remarks’ section. For example, stats tell us that ‘30% of trips and falls are from elevated surfaces,’ this detail, which might seem odd if mentioned in previous steps, is vital to know the level of risk elevated steps can pose in a kitchen.