The Criteria for Food Safety Certification

The registration process to gain a food safety certification ensures that our products have met the following criteria:

- To ensure compliance with food safety standards, cleaning products are not permitted to contain intentionally added heavy metals, carcinogens, or mutagens.

- If a cleaning product or sewage/drain cleaner contains bacterial or enzyme cultures, testing and analysis are required to ensure that it does not introduce new live bacteria, such as Salmonella.

- Cleaning products should not have a noticeable odour or leave a visible residue on surfaces.

4. If a cleaning product contains fragrance, it must undergo testing to ensure that the scent does not mask an odour associated with a food safety issue, such as food spoilage.

5. When used as directed, antimicrobial products must not contaminate food products and should be verified accordingly.

Ensuring Product Safety and Compliance

Moreover, food safety certification product registration requirements ensure that:

- Your cleaning product labels include clear instructions for use that are consistent.

- The registration body has also reviewed the intended use of the cleaning product, adding another layer of assurance that the product is safe for use in food-related environments.

ORAPI Tips: Best Cleaning Chemicals to Use

While several chemicals are effective in combating the most prevalent foodborne pathogens, there are a few that are most effective for this purpose.

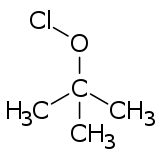

HYPOCHLORITES

When combined with an inorganic compound like calcium or sodium, chlorine creates hypochlorites, commonly used in food processing environments to sanitize surfaces. However, the effectiveness of hypochlorites depends on various factors, including the level of cleanliness of the surfaces prior to application, the pH of the solution, its concentration, the temperature of the facility, and the duration of contact time.

However, hypochlorites prove to be excellent disinfectants due to their many benefits.

- It is a powerful oxidizing agent that quickly destroys bacteria, viruses, and other harmful microorganisms.

- Hypochlorite is fast-acting, which helps to ensure that the surface is free of germs.

- It is also affordable and easy to use, as it can be easily used without requiring any specialized equipment or training.

- Hypochlorite has a long shelf life and remains stable when stored properly.

ORAPI RECOMMENDS:

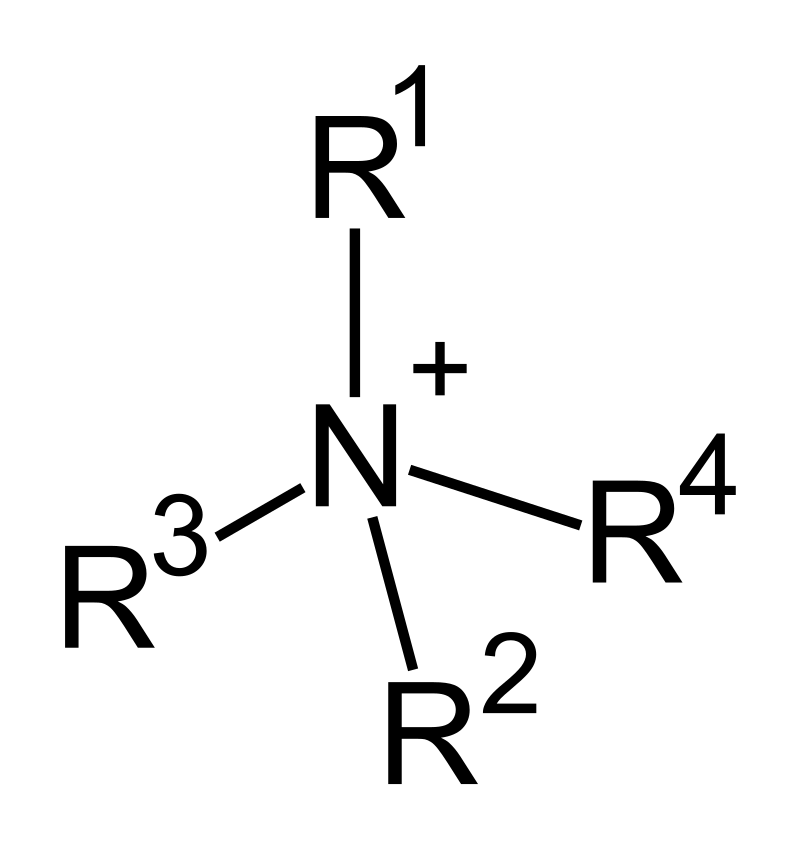

QUATERNARY AMMONIUM COMPOUNDS

Quaternary ammonium compounds (QACs) are organic compounds widely used as disinfectants in the food industry due to their antimicrobial properties. QACs bind to negatively charged surfaces such as cell membranes, disrupting cells by forming hydrophilic voids. They are effective against lipophilic microorganisms, particularly gram-positive bacteria and enveloped viruses, but are generally not sporicidal and are ineffective against hydrophilic viruses

DISAKLEEN is a neutral concentrated detergent & disinfectant, developed for surface cleaning applications in the food, beverage and dairy industries. It also is formulated with a blend of foaming detergents, sequestrants and quaternary ammonium compounds specially selected to be highly effective against most vegetative forms of micro-organisms including Gram-positive & Gram-negative bacteria & yeasts, and enveloped viruses**.

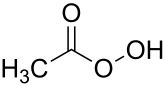

PEROXYACETIC ACID (PAA)

Peroxyacetic acid is a disinfectant that breaks down the chemical bonds within the cell membranes of bacteria and other microorganisms. It is often used in combination with hydrogen peroxide and is effective in cold conditions, making it suitable for refrigeration units in food processing environments. PAA is also effective for biofilm removal, which is a common problem in food processing plants. Unlike hypochlorites, PAA is more effective, less corrosive, and environmentally friendly since it breaks down into acetic acid, oxygen, and water.

NSF-CERTIFIED ORAPI PRODUCTS

Choosing the right cleaning chemicals for your food industry facility can be a difficult task for any manager responsible for Food Safety and Quality Assurance (FSQA). However, using ORAPI products can demonstrate your commitment to safety standards and guarantee the health of your customers. ORAPI is listed in the NSF White Book, ensuring our products are effective and safe for all food processing facilities.

Conclusion

In conclusion, the food and beverage industry must ensure that cleaning products used for processing, handling, or cooking are safe and meet food safety standards. Registering cleaning products with independent third-party assurance providers, such as NSF, effectively demonstrates product suitability, compliance with regulations, and safety for food industry applications. Using recommended cleaning chemicals, such as hypochlorites, quaternary ammonium compounds (QACs), and peroxyacetic acid (PAA), is also an essential part of the cleaning process for any food industry facility. Choosing suitable cleaning chemicals is critical for food industry managers responsible for food safety and quality.