In a previous article, we elaborated on the 11 distinct types of corrosion. If you’ve gone through that piece, you should now be able to differentiate between these forms. However, a question that may linger in your mind is, “Within a large apparatus like an aeroplane, where is corrosion most likely to manifest?” To address this query, this article will explore the top 10 regions susceptible to corrosion. These specific areas prone to aircraft corrosion require more frequent cleaning, inspection, and treatment than less corrosion-prone regions.

Aircraft Corrosion: Common Corrosive Agents

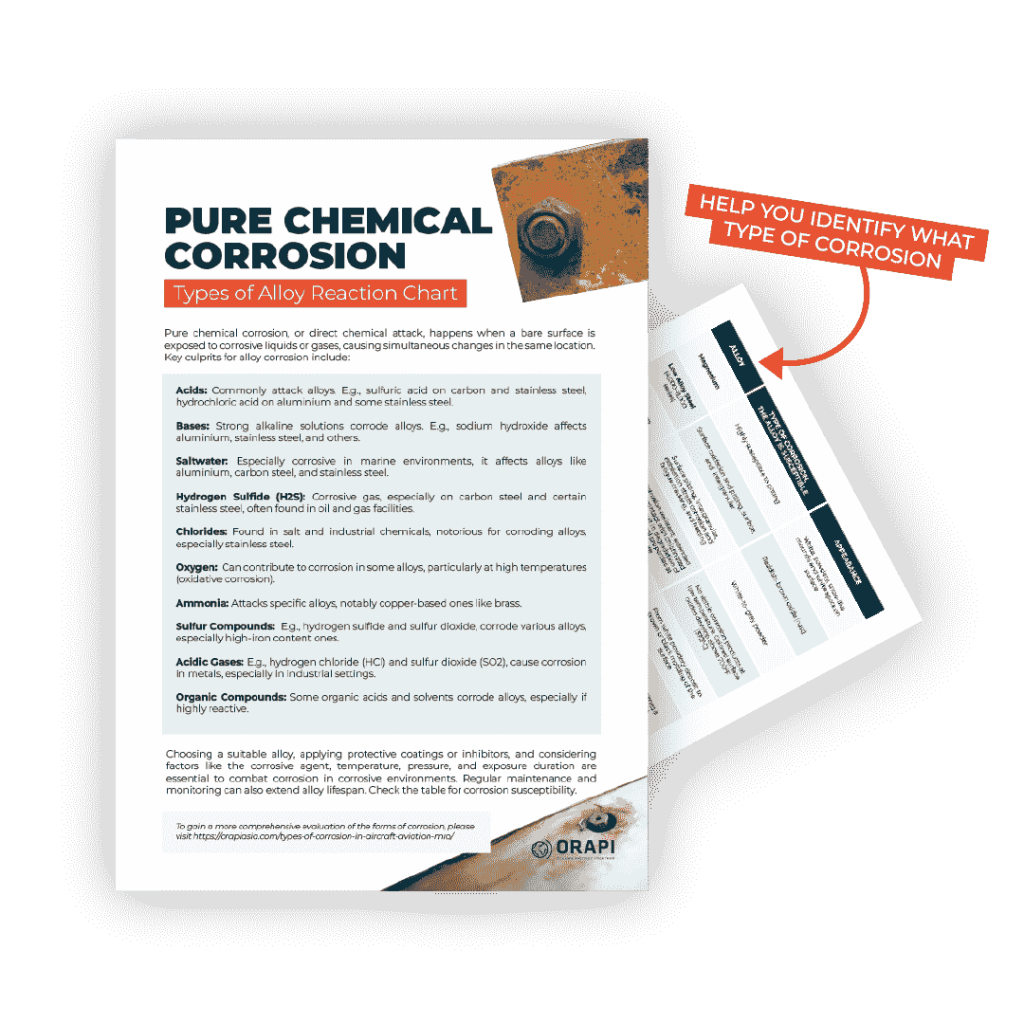

Corrosive agents encompass a variety of substances, including acids, alkalis, and salts. Additionally, both the atmosphere and water, the two most frequent mediums for these agents, can also act as corrosive substances.

Acids

Airframe alloys are vulnerable to significant corrosion caused by moderately strong acids. The highly destructive acids include sulfuric acid (battery acid), halogen acids such as hydrochloric, hydrofluoric, and hydrobromic, as well as nitrous oxide compounds and organic acids present in human and animal waste.

Alkalis

Alkalis, when considered collectively, exhibit lower corrosiveness compared to acids. However, aluminium and magnesium alloys are especially vulnerable to corrosion caused by several alkaline solutions unless these solutions contain a corrosion inhibitor. Some substances, such as washing soda, potash (wood ashes), and lime (cement dust), are particularly harmful to aluminium. Aluminium alloys are highly resistant to ammonia, an alkali, which is an exception.

Salts

Salt solutions can be problematic as they often act as good electrolytes, leading to corrosive damage. While some stainless-steel alloys are resistant to this type of attack, other materials such as aluminium alloy, magnesium alloys, and certain steels are particularly vulnerable. As a result, it is highly undesirable to expose airframe materials to salts or their solutions.

Atmosphere

The elements in the atmosphere that cause corrosion are oxygen and moisture in the air. The metal corrodes when these agents come in direct contact with it, and in high-humidity areas, excess moisture speeds up the process, especially in ferrous alloys. Other harmful gases and pollutants, specifically industrial and marine salt spray, may also be found in the atmosphere.

Water

The corrosive nature of water depends on several factors, including the composition and concentration of dissolved minerals, organic substances, and gases, notably oxygen. Water’s conductivity, which enables it to function as an electrolyte and facilitate electrical conduction, also determines its corrosive potential. Physical variables like water temperature and flow rate also directly influence its corrosion propensity.

1. Aircraft Corrosion in Exhaust Trail Areas

2. Battery Compartments and Battery Ventilation

Despite advancements in protective coatings and sealing techniques, battery compartments remain susceptible to corrosion. It is challenging to contain fumes emitted by overheated electrolytes, which can easily spread to adjacent areas, leading to rapid corrosive damage to unprotected metal surfaces. Including aircraft skin battery vent openings in the inspection and maintenance regimen for battery compartments is vital. When aircraft batteries utilise electrolytes such as sulfuric acid or potassium hydroxide, any leakage can result in corrosion. To mitigate this, regular cleaning and neutralisation of acid deposits are necessary to minimise corrosion.

3. Aircraft Corrosion in Bilge Areas

4. Lavatories, Buffets, and Galleys

These zones, especially the deck spaces adjacent to restrooms, sinks, and cooking facilities, can become problematic if cleanliness isn’t maintained. They are susceptible to the accumulation of spilt food and waste materials. Even though certain contaminants may not be inherently corrosive, they tend to draw in and retain moisture, leading to corrosive damage over time. Be cautious of bilge sections situated beneath kitchenettes and restrooms. Regularly clean these regions and maintain the protective sealant and paint coatings.

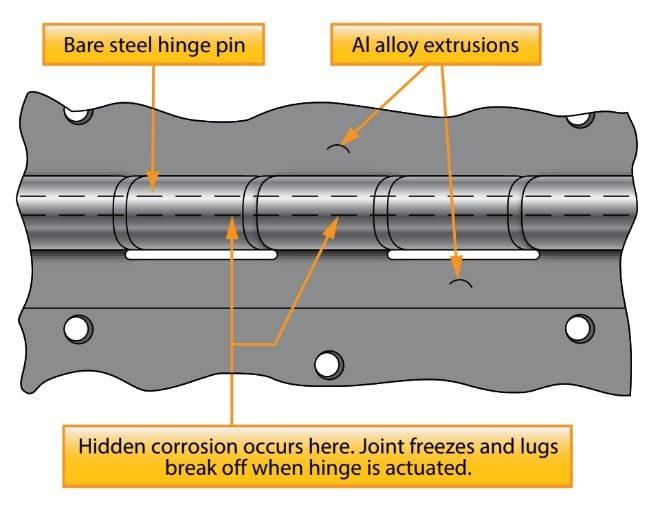

5. Wheel Well and Landing Gear

The undercarriage of an aircraft is subject to a lot of wear and tear from various elements such as mud, water, salt, and small flying debris. It is a complex area with many different shapes, fittings, and assemblies, making it difficult to achieve and maintain complete paint coverage. Simply applying preservatives to the area can mask corrosion instead of preventing it. Additionally, due to the heat generated by braking, preservatives cannot be used on some of the main landing gear wheels.

During inspection, it’s important to carefully examine these problematic areas:

- Inspect magnesium wheels for any signs of entrapped water or its effects, paying special attention to bolt heads, lugs, and wheel web areas.

- Check exposed rigid tubing for potential issues, especially around B-nuts, ferrules, clamps, and tubing identification tapes.

- Examine exposed electrical equipment, including position indicator switches and other electrical components.

- Investigate crevices between stiffeners, ribs, and lower skin surfaces, as these are common water and debris accumulation areas.

- Inspect axles interiors.

- Evaluate the exposed surfaces of struts, oleos, arms, links, and attaching hardware (such as bolts and pins).

6. Water Entrapment Areas

To meet design specifications, aircraft must have drains installed in areas where water may accumulate. It is a standard requirement to inspect low-point drains daily. Neglecting this inspection can result in clogged drains due to debris, grease, or sealant buildup.

When salt enters a moist environment, it increases electrical conductivity and inhibits the formation of protective oxide layers on certain metals. This prevents these metals from resisting corrosion. The composition of the solution on metal surfaces, along with factors like temperature, directly affects electrical conductivity and corrosion speed. In situations with gaps or trapped stagnant water, higher metal ion concentration can occur, creating an electrical potential that promotes corrosion. Elevated corrosive pollutant levels may lead to metal ion buildup on structures, especially in cyclical wetting and drying conditions.

7. Engine Frontal Areas & Cooling Air Vents

The constant exposure to airborne dirt and dust, along with erosion caused by rain and bits of gravel from runways, can lead to the removal of the protective finish on these areas. Additionally, certain parts of the engine, such as radiator coolers and reciprocating engine cylinder fins, cannot be painted due to the need for heat dissipation. Moreover, engine accessory mounting bases often have small unpainted magnesium or aluminium areas on their machined-mounted surfaces. Therefore, inspecting all sections in the cooling air path is crucial, paying special attention to places where salt deposits may accumulate during marine operations. It is essential to proactively inhibit the onset of corrosion and ensure that seaplane and amphibian engine surfaces are consistently maintained with paint touch-ups and durable preservative coatings.

8. Wing Flap & Spoiler Recesses

Dirt and water can accumulate in the recesses of flaps and spoilers, often unnoticed due to their retracted position. As a result, these recesses pose a potential corrosion risk. We recommend inspecting these areas when the spoilers and flaps are fully extended.

9. External Skin Areas Aircraft Corrosion

10. Electronic & Electrical Compartments

11. Miscellaneous Aircraft Corrosion Areas

Conclusion: Aircraft Corrosion Prone Areas

In conclusion, understanding the various forms of aircraft corrosion is essential for the maintenance and longevity of aircraft. This article has provided valuable insights into the top 10 regions susceptible to corrosion within an aircraft. From exhaust trail areas to battery compartments, wheel wells to electronic compartments, these areas demand vigilant cleaning, inspection, and treatment to prevent and mitigate corrosion. Furthermore, it emphasises the importance of regular maintenance, protective coatings, and sealants to safeguard against the destructive effects of corrosive agents. By addressing these specific areas, aviation MRO specialists can ensure the safety and reliability of their fleets, ultimately contributing to safer skies and more efficient operations in the aviation industry.