Aerosol Products Offers Convenience Of Use

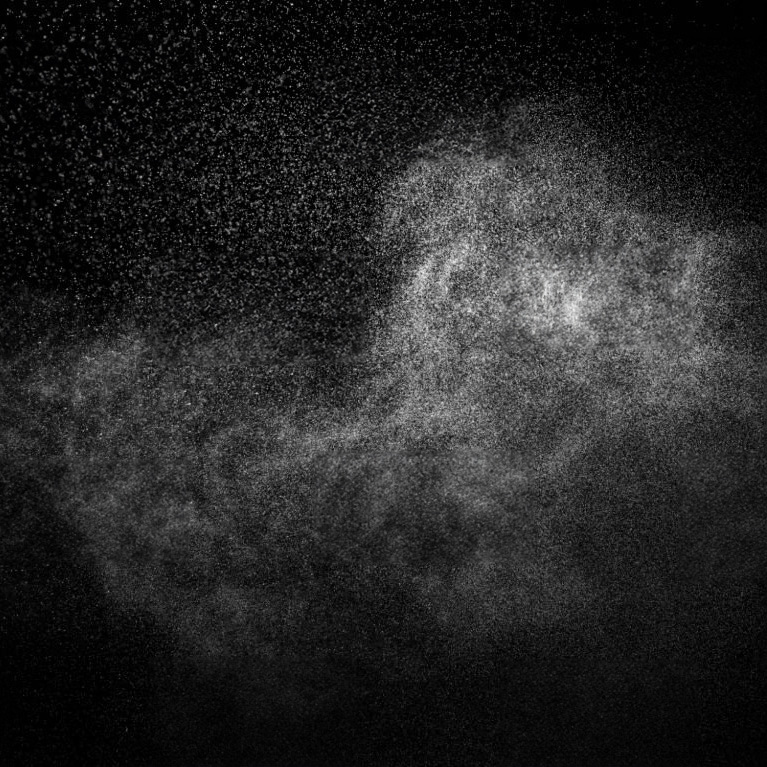

Uniform Application

This mist or spray has several advantages when it comes to achieving a uniform application:

1. Even distribution

The atomised particles are dispersed to allow for a more even product distribution. As the mist or spray is released from the nozzle, it forms a cloud of fine droplets that spread in a wide pattern, enabling the product to reach a larger surface area. This ensures that it is applied evenly and uniformly.

2. Enhanced Coverage

The fine mist or spray produced by aerosol products provides better coverage than other packaging forms. The atomised particles are smaller, allowing them to coat the target surface more effectively. This results in a smoother and more consistent application, without clumps or streaks that may occur with other application methods.

3. Reduced Waste

The atomisation process of aerosol cans helps minimise product wastage. By breaking down the product into tiny droplets, the aerosol ensures that a larger proportion is effectively dispersed and utilised. This reduces the chances of overapplication or excess product being deposited in one area, leading to more efficient product use and less waste.

Enables Users to Avoid Messy Application

ORAPI RECOMMENDS:

- SBR adhesive in aerosol for the bonding of all “light” elements.

- Bonding of light materials: fabrics, paper, felt, cardboard, photos, leather, glass, plastics, on wood, glass, metals,

- Industry: bonding of labels on plastic or metallic casks and cans.

- Graphic arts: bonding proof copies on paper and bonding advertisements on billboards.

- Car industry: interior bonding of fittings on coachworks.

- House: bonding of light false ceilings, restoration of wallpapers, bonding of furniture covering (melamine resins, Formica).

Controlled Dispensing

Controlled dispensing helps reduce the likelihood of the excessive product being applied. With traditional application methods, there is a higher risk of accidentally using too much adhesive, leading to messy and wasteful outcomes. In contrast, aerosol cans with nozzles allow users to regulate the amount of adhesive being dispensed. By controlling the pressure applied to the nozzle or adjusting the nozzle settings, users can release a fine mist or spray that covers the intended area without over-saturating it. This not only prevents the wastage of adhesive but also minimises the mess associated with excess product.

Precise Targeting

One of the critical advantages of controlled dispensing is its ability to provide precise targeting. When using other application techniques, such as brushes or squeeze tubes, applying the product exactly where needed can be challenging. However, with aerosol products and nozzles, users can direct the spray precisely onto the desired area, ensuring accurate application. This is particularly beneficial when working with intricate or small surfaces, where precision is crucial.

Access Inaccessible Areas

Aerosol products with nozzles offer convenience in product application in hard-to-reach areas. The directed spray allows users to reach inaccessible spots or intricate surfaces, such as corners, crevices, or complex shapes, with greater ease and precision, eliminating the need for manual manipulation or potential mess when applying the product in those areas.

Preservative Properties

Preservative properties are crucial for aerosol packaging, particularly with paints, insecticides, and personal care items. The propellant acts as a protective barrier, preventing air and contaminants from entering the can and degrading the product. This reduces spoilage risks and maintains quality. Aerosol packaging also shields against external factors like air and moisture, which can compromise paint usability, insecticide potency, or personal care item shelf life. The propellant creates an airtight seal, preserving the contents and extending their lifespan. Some propellants even possess antimicrobial or antifungal properties, further safeguarding against contamination.

ORAPI RECOMMENDS:

Conclusion

In conclusion, aerosol products have gained significant popularity across various industries due to their unique characteristics and advantages. The convenience of use provided by aerosol cans, with their effortless application process and precise targeting capabilities, appeals to consumers seeking efficiency in their daily routines. The uniform application achieved through atomisation ensures even distribution, enhanced coverage, and reduced waste, making aerosol cans ideal for paints, adhesives, air fresheners, and grooming products. Moreover, the controlled dispensing offered by aerosol cans allows users to regulate the amount of product being applied, minimising mess and wastage. Additionally, the preservative properties of aerosol packaging, including the protective barrier created by the propellant, ensure product longevity and safeguard against contamination.