Welcome to the third instalment of Grease 101. In PART 1 of the series, we provided an overview of grease lubricants, covering aspects like base penetrability, NLGI grade classification, grease drop-point, and dmN factor measurement. In PART 2, we explored lubricating oil and thickeners, elucidating their types and inter-compatibility. This third and final part of the series is dedicated to additives, the third grease lubricant component. We’ll delve into their various types, assess advantages and constraints, and conclude with a rundown of greasing techniques.

Additives Definition

Additives are components added to lubricating oils to enhance their performance, particularly in boundary lubrication situations where two surfaces are in direct contact. These additives can exist in either liquid or solid forms.

Liquid Additives

Anti-wear Agents

Anti-wear agents are additives that serve to prevent the wear and tear of surfaces that are in motion. These agents form a protective layer on the surface, minimising friction and reducing the likelihood of damage due to mechanical contact between moving parts. By creating a barrier between the surfaces, they help extend the lifespan of the lubricated components.

Anti Oxidizing Agents

In high-temperature conditions, lubricating oils can experience oxidative degradation, leading to reduced performance and the formation of harmful byproducts. Anti-oxidising agents are added to the oil to counteract these effects. They work by inhibiting the chemical reactions that cause oil to break down under high temperatures, extending the oil’s usable life and maintaining its effectiveness.

Anti-Rust Agents

Lubricated components are often exposed to environmental factors like water and humidity, which can lead to corrosion and rust formation. Anti-rust agents are incorporated into the lubricating oil to enhance its resistance against these factors. These additives form a protective barrier on metal surfaces, preventing moisture penetration and inhibiting the formation of rust, which helps maintain the integrity of the components.

Extreme Pressure Agents (EP)

When lubricated surfaces are subjected to high loads or extreme pressures, the lubricating film can be squeezed out, resulting in direct metal-to-metal contact. Extreme pressure agents are included in the oil to address this issue. They chemically react with the metal surfaces under high pressure, forming a protective layer that prevents welding and galling of the surfaces. This ensures that the lubricating film remains intact even under heavy loads, reducing friction and wear.

Adhesion Agents (Synthorium)

Adhesion agents are specialised additives that enhance the oil’s ability to adhere to surfaces. Synthorium is an adhesion agent that improves the oil’s affinity to stick to surfaces, even under demanding conditions. This is particularly useful when the lubricating film could be displaced due to movement or vibration. By promoting stronger adhesion, these agents ensure the lubricating film remains in place, maintaining a consistent barrier between moving parts.

Solid Additives

Solid additives enhance the efficacy of grease lubricant in extreme conditions where base oil alone may not suffice due to high temperatures, extreme temperatures, pressures, or other challenging environments. Additionally, in situations where the base oil’s viscosity might break down or fail to adequately separate moving surfaces, solid additives provide an additional layer of protection.

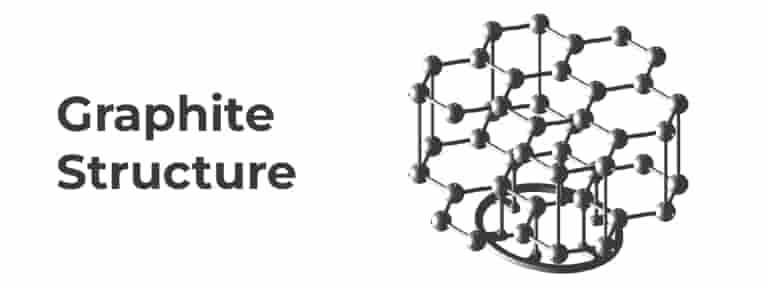

Graphite

Over 99% Carbon

Graphite is composed primarily of carbon atoms arranged in a hexagonal lattice structure.

Lamellar Hexagonal Structure

Graphite’s structure consists of closely packed layers of carbon atoms arranged in a hexagonal pattern. These weakly bonded layers can easily slide over one another, giving graphite its lubricating properties.

Good Dry Lubricant

The layered structure allows individual sheets to slide smoothly, reducing surface friction.

Excellent Resistance to High Temperatures (900°C)

Graphite exhibits exceptional thermal stability. It can withstand high temperatures without undergoing significant chemical changes or degradation.

Good Electrical Properties

Due to its high electrical conductivity, graphite is often used in applications requiring electrical conductivity, such as in electrical brushes, contacts, and certain industrial processes.

Good Thermal Conductivity

Graphite also possesses good thermal conductivity, allowing it to dissipate heat effectively. This property makes it suitable for use in applications where heat needs to be managed, such as in heat sinks or thermal management systems.

Good Anti-Corrosion Properties

Graphite’s layered structure and chemical inertness contribute to its anti-corrosion properties. It can act as a barrier, protecting surfaces from corrosive elements and preventing direct contact between metals that might lead to galvanic corrosion.

Moderate Adhesion to Surfaces

Graphite exhibits moderate adhesion to surfaces. While it doesn’t firmly adhere like some other materials, its slight adhesion can be beneficial in helping the graphite particles to stick to the surfaces they need to lubricate.

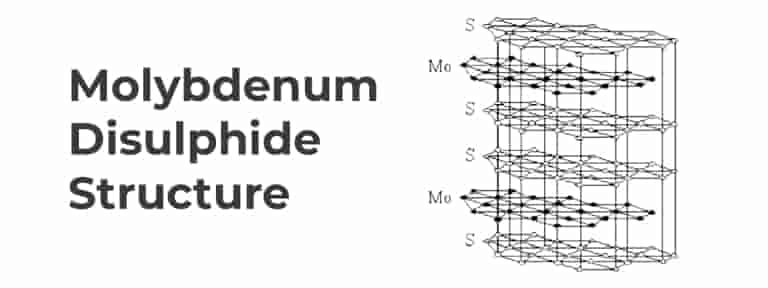

Molybdenum Disulphide (MoS2)

Found in Granite Veins and Highly Refined

Molybdenum Disulfide (MoS2) is a mineral found in granite veins and other geological formations. It’s often refined and processed for industrial applications to achieve specific purity levels and particle sizes suitable for various uses.

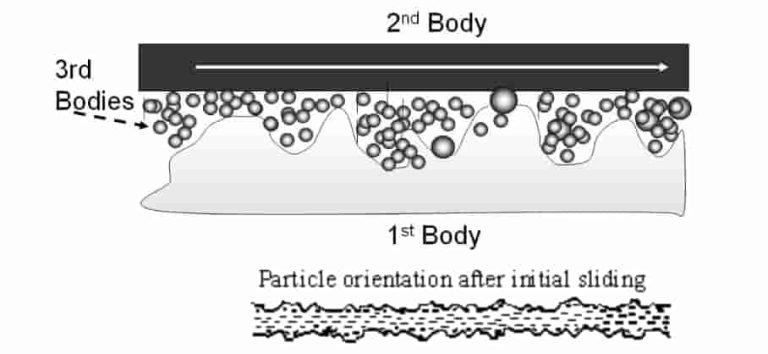

Lamellar Hexagonal Structure with Easy Shear Property

Similar to graphite, MoS2 has a layered, hexagonal lattice structure. This structure allows the individual layers to easily shear or slide over one another, which gives MoS2 its exceptional lubricating properties.

Excellent Dry Lubricant

Its lamellar structure enables it to create a boundary layer between surfaces, reducing friction and wear even in the absence of traditional liquid lubricants.

High Extreme Pressure (EP) Performance

MoS2 excels in extreme pressure conditions where metal surfaces are subjected to heavy loads and pressures. It forms a protective layer that prevents direct metal-to-metal contact and helps prevent wear, galling and other surface damages.

Excellent Adhesion to Surfaces

MoS2 exhibits strong adhesion to metal surfaces, which enhances its ability to stay in place and provide consistent lubrication even under demanding conditions.

Non-Conductive

This property is beneficial in applications where electrical conductivity must be avoided or minimised.

Corrodes Metals at High Temperatures (450°C)

One limitation of MoS2 is that it can promote corrosion in certain metals at high temperatures, around 450°C and above. This corrosion occurs due to the MoS2 particles’ interaction with the metal surface under specific conditions.

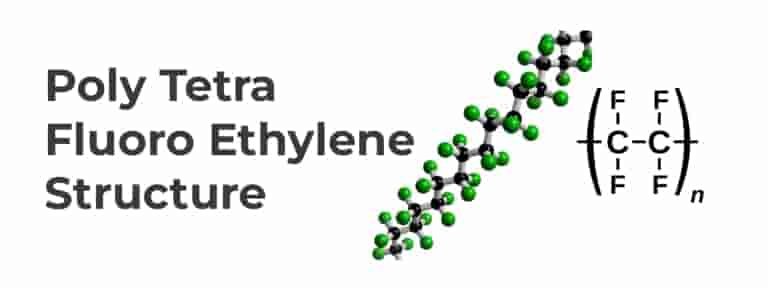

Poly Tetra Fluoro Ethylene (PTFE)

Excellent Friction Coefficient due to Low Surface Energy

PTFE is known for its remarkable lubricating properties, primarily attributed to its deficient surface energy. This property results in an exceptionally low friction coefficient, often as low as 0.04 or even lower, making it an ideal choice for reducing friction and wear between surfaces.

Not Layered Structure

Unlike graphite and molybdenum disulfide, PTFE does not have a layered structure. Instead, it consists of long, linear molecules with strong carbon-fluorine bonds. This unique structure contributes to its self-lubricating properties.

Macromolecules Slip Easily Along Each Other

The long-chain molecules in PTFE are slippery, allowing them to slide past each other with minimal resistance.

White Color

PTFE is naturally white in colour, which can be advantageous in applications where the appearance of the lubricated components is important.

Food Grade

PTFE is approved for use in food-related applications due to its non-toxic and non-reactive nature. It is often used in food processing and packaging machinery.

Operating Temperature Limited to 260°C

While PTFE offers excellent lubricating properties, its operating temperature is limited to around 260°C (500°F). Beyond this temperature, PTFE can begin to degrade, potentially affecting its performance and introducing other considerations like outgassing.

Metallic Salts

Lubrication

Certain metallic salts possess inherent lubricating qualities, helping to reduce friction and wear between surfaces. This can be particularly beneficial in applications where solid lubrication is preferred over liquid lubricants.

Adhesion to Surfaces

Metallic salts can enhance the adhesion of the grease lubricant to surfaces, ensuring that the lubricant remains in place even under challenging conditions. This improved adhesion contributes to longer-lasting lubrication and protection.

Conductivity

Some metallic salts, like certain compounds of zinc and selenium, can offer electrical conductivity. This can be advantageous in applications where maintaining electrical contact or grounding is necessary.

Limited Usage

While metallic salts can provide valuable properties to grease lubricant formulations, they are not as commonly used as other solid additives like graphite or molybdenum disulfide. The selection and use of metallic salts as additives depend on the specific lubrication requirements and the salts’ compatibility with the other grease components.

Types of Metallic Salts

Each of these metallic salts offers unique characteristics:

Titanium

Titanium compounds are used for their anti-wear and extreme pressure properties.

Zinc

Zinc-containing additives are often used for their anti-corrosion properties.

Boron

Boron compounds contribute to reducing friction and preventing surface degradation.

Selenium

Selenium-based additives can provide electrical conductivity and anti-wear properties.

Why Are Greasing Methods Necessary

Greasing methods are crucial in maintaining ball and roller bearings’ optimal performance and longevity. These methods ensure that the bearings are properly lubricated to reduce friction, heat generation, and wear, ultimately preventing premature failure.

Minimal Lubrication Requirement

Ball and roller bearings have a specific design allowing them to operate effectively with minimal lubricant. They do not require excessive quantities of lubrication to function properly.

Lubrication Mechanism

In these bearings, lubrication is primarily facilitated by a small quantity of oil that gradually seeps out from the grease base. This oil forms a thin film on the bearing surfaces, reducing friction and enhancing smooth operation.

Grease Lubricant Movement

For optimal performance, it’s essential that the lubricant actively circulates within the bearing. This movement helps to distribute the lubricating oil evenly and prevents localised areas of friction and heat buildup.

Disadvantages of Complete Filling

While it might seem logical to fill bearings with grease lubricant, doing so can lead to certain issues, especially at higher speeds

Overheating

Excessive grease lubricant can lead to higher levels of friction, generating excess heat. This heat can degrade the grease and potentially damage the bearing components.

Excessive Oil Leakage

The excess grease can force out excess oil, leading to oil leakage from the bearing. This not only wastes lubricant but also increases the risk of contamination and reduces lubrication effectiveness.

Premature Failure

The combination of overheating and inadequate lubrication due to improper grease distribution can contribute to premature bearing failure.

When Complete Filling is Necessary

There are specific scenarios in which bearings and their housings should be filled and the fill maintained:

Slow Speed Operation

At slow speeds, the excess grease lubricant does not generate as much friction and heat, making complete filling less likely to cause issues.

Poor Sealing

In cases where the sealing mechanisms are not efficient, a complete fill of grease might be necessary to compensate for potential leakage.

Dusty Operating Environment

Bearings operating in dusty or harsh environments can benefit from complete filling, as the excess grease can help prevent dust and contaminants from entering the bearing and compromising its performance

Initial Greasing Process

Removal of Corrosion Protective Film

During manufacturing, bearings are often coated with a corrosion-protective film to safeguard them from environmental influences. However, this film must be removed before the bearing is put into operation. To achieve this:

- A suitable solvent is used to wash off the protective film without damaging the bearing components.

- Thorough washing ensures that no residue of the protective film remains on the bearing. Any remaining residue could interfere with the grease’s ability to adhere to the bearing surfaces and distribute effectively.

Bearing Drying and Cleanliness

After removing the protective film, it’s important to ensure the bearing is completely dry and free from contaminants or grit.

- The drying process is typically carried out in a controlled environment to prevent moisture accumulation and expedite the evaporation of any solvent used during the cleaning process.

- Any particles or foreign materials, such as dust or grit, must be removed from the bearing surfaces to prevent interference with proper grease lubricant distribution and the overall bearing function.

Light Coating of Grease Lubricant

With the bearing components now clean and dry, the next step involves applying a light coat of grease to key areas, which include the tracks (races), cage, and rolling elements (balls or rollers).

- Ensure even grease distribution across the bearing components to establish a consistent lubricating film that reduces friction and wear.

- Facilitate the formation of a lubricating layer between the rolling elements and tracks, minimising direct metal-to-metal contact and associated frictional losses.

It’s important to note that while applying grease lubricant, care must be taken not to over-grease the bearing. Over-greasing can lead to excess heat generation, inadequate lubricant circulation, and potential leakage.

Relubrication Process for Bearings

Cleaning the Grease Nipple or Fitting

The process starts by ensuring the grease nipple or fitting is free from accumulated grease, dirt, or grit. This step is crucial because contaminants present on the grease nipple can be introduced into the bearing during the relubrication process, potentially leading to premature wear or damage.

Pumping in the Required Quantity of Grease Lubricant

The amount of grease to be applied depends on factors such as the bearing size, operating conditions, and manufacturer recommendations. The process involves using a grease gun or lubrication device.

Grease Lubricant Application Quantity

The quantity of grease lubricant to be applied is often specified by the bearing manufacturer or maintenance guidelines. A standard cartridge gun typically applies around 2 grams of grease per shot. However, the specific requirements may vary based on the bearing type and application.

Cleaning the Nipple After Greasing

This step ensures that any excess grease lubricant or contaminants are removed, preventing the accumulation of grease around the nipple and maintaining a clean environment.

Conclusion: Grease Lubricant Additives and Application

In conclusion, in the Grease 101 series, we provided a comprehensive exploration of grease lubricants, from fundamental concepts to detailed additive components. Through this three-part journey, we’ve covered essential topics, including grease properties, lubricating oil types, thickeners, and, finally, additives. Additives enhance grease performance by mitigating wear, countering oxidation, preventing rust, addressing extreme pressures, and improving adhesion. Both liquid and solid additives extend the lifespan and effectiveness of lubricated components. By understanding the intricate interplay of these components, engineers and maintenance professionals can make informed decisions to optimise greasing methods and ensure the reliable operation and longevity of various mechanical systems.