Wastewater management is a critical aspect of the food processing industry due to the large quantities of wastewater generated during the production of various food products, including fruits and vegetables, fish, meat, poultry, dairy products, and fats and oils. However, managing this wastewater is a challenging task, as it can contain high levels of nutrients, organic carbon, nitrogenous organics, inorganics, suspended and dissolved solids, and high biochemical and chemical oxygen demands. Furthermore, excessive discharge of untreated wastewater can cause harm to receiving waters and disrupt publicly owned treatment works (POTW).

It is also important to note that plant-food processing waste may have a greater volume but lower strength than animal processing and production waste. Therefore, effective wastewater management is crucial to ensure compliance with regulations and minimise environmental and health risks. Keep reading to uncover the essential insights into wastewater management that every conscientious consumer and industry professional should know.

The Diversity of Wastes

Various food and agricultural wastes pose distinct challenges, including meat and poultry, dairy products, canned and preserved fruits and vegetables, grain products, sugar, confectionaries, fats and oils, beverages, brewing, and more. In addition, numerous wastes have biochemical oxygen demand (BOD) and chemical oxygen demand (COD) values that are thousands of milligrams per litre, while others, like cheese production, winery, and olive milling, can have tens of thousands of COD. As a result, each waste type necessitates careful consideration of unique factors, and in addition to technical performance concerns, seasonal production complicates treatment options and operations in several industries.

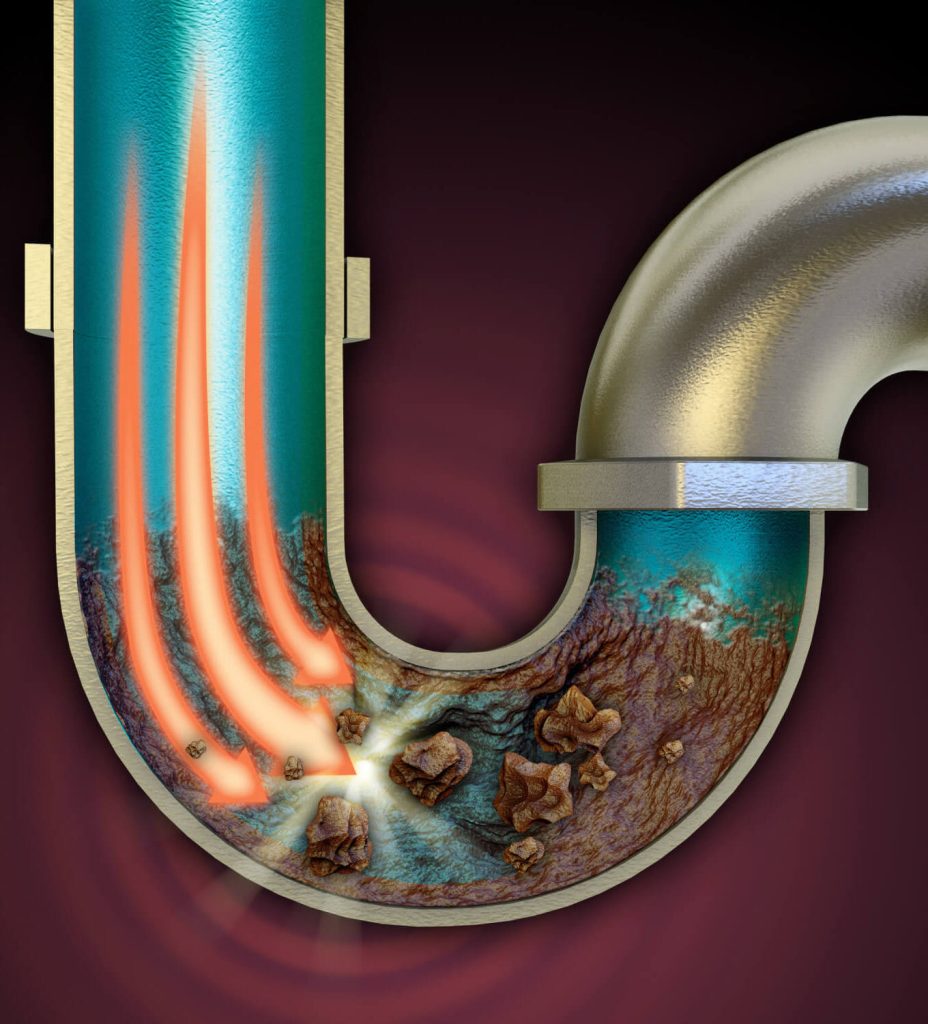

Drain Lines in Wastewater Management

Drain lines are an essential aspect of wastewater management in the food processing industry, serving as the pipes and channels that carry wastewater from processing areas to treatment and disposal facilities. Therefore, proper maintenance and cleanliness of drain lines are necessary to prevent blockages and ensure that wastewater flows smoothly through the system. Wastewater from food processing plants can contain harmful pathogens, and drain lines must be designed and maintained to prevent biofilm buildup and other microbial contamination sources. Additionally, drain lines can be utilised to segregate different types of wastewater streams, preventing cross-contamination and ensuring proper treatment and disposal. Regular inspection and maintenance of drain lines are critical to prevent leaks and the release of untreated wastewater into the environment.

Septic Systems in Wastewater Management

Septic systems are designed to treat wastewater naturally through the breakdown of organic matter by bacteria and other microorganisms. This process helps remove contaminants from wastewater and makes it safe for disposal. Additionally, septic systems can be a cost-effective alternative to expensive wastewater treatment plants and offer flexibility in handling different types and volumes of wastewater. However, compliance with regulations and permits is essential to ensure that septic systems function correctly and do not cause harm to the environment or human health.

Drain Taps Wastewater Management

Drain taps are valves or taps used to regulate wastewater flow from processing areas to the drainage system or treatment facility. They control the flow of wastewater and regulate the amount of discharge, allowing effective wastewater management. Drain taps can also segregate different types of wastewater streams, preventing cross-contamination. Regular maintenance and cleaning of drain taps are essential to prevent blockages, backups, and overflows that can cause environmental and health problems. Compliance with regulations and permits is mandatory for the discharge of wastewater from food processing plants. Therefore, drain taps must be installed and operated in compliance with these regulations to avoid legal penalties and ensure wastewater’s safe and effective disposal.

Methods for Effective Treatment of Wastewater

Treatment methods commonly used for treating wastewater from food processing typically include a range of biological and physical-chemical treatments, and both oxidative and anaerobic processes can be used. These treatment methods can consist of flotation, coagulation, sedimentation, filtration, adsorption, membranes, primary settling, secondary activated sludge, anaerobic digestion, and even the recovery of carbon dioxide or methane for reuse. Furthermore, some of the treated residues or waste can be used as beneficial soil amendments or fertilisers to help reduce concerns surrounding wastewater discharge. However, excessive nutrient runoff, especially during cold weather, can still pose challenges even with these approaches.

Incorporating in-plant recycling is another viable option since water is a precious resource required not just for food processing but also for cleaning equipment, facilities, and floors. To facilitate non-food contact applications, detergents or other additives may be employed, which can potentially enhance or complicate subsequent treatment processes. However, ensuring the safety of the food product is of utmost importance, and recycling within a process step is permitted by law for certain food processing methods, such as the use of chiller water in meat and poultry processing. Nevertheless, recycling between different food processing methods that involve food contact surfaces can be challenging since various contaminants may be introduced.

Fruit and Vegetable Processing

Vegetable and food processing wastewater often involves the utilisation of several of the treatment processes discussed earlier. In addition, the production process generates various waste streams that include but are not limited to washing and rinsing, sorting, in-plant fluid transport methods, peeling, pureeing and juicing, blanching, canning, drying, cooking, and cleanup. The majority of waste content is made up of biodegradable carbohydrates; however, for some products, salts from brining may also contribute to the waste stream.

Fishing Sector

The production of fish products involves several stages that result in the generation of both solid and liquid wastes. The harvested product may be processed onboard the fishing vessel; alternatively, it may be stored by icing or freezing to facilitate transportation to the processing plant. In the case of farmed fish, the handling process may differ from that of wild-caught fish. Waste from evisceration and butchering is collected, dried, or screened and repurposed as byproducts. The processing plant may also trim the product and further process it by cooking, packing, or freezing, creating additional liquid and solid wastes. Each type of product generates different levels of BOD and COD, and significant quantities of fats, oils, grease, and protein content may also be present.

Meat and Poultry Processing

The meat and poultry industries generate a variety of waste products, including those produced by the animals during livestock holding and high-strength wastes generated during processing. The processing stages include slaughtering, de-feathering or hide removal, eviscerating and trimming, washing, disinfecting, and cooling. Poultry plants, in particular, may process up to two million birds each week, making them significant waste generators on a large scale. The waste components consist of substantial amounts of nitrogenous organic compounds (proteins), fats, and inorganic compounds (nitrates).

Dairy Industry

The milk industry comprises two primary elements: milk bottling and milk product production. Milk product production includes the processing of whey, butter, cheese, ice cream, yoghurts, cottage cheese, and other milk derivatives. This stage is the largest contributor to wastewater production and its strength. In particular, COD levels in cheese production can be more than ten times higher than in milk bottling. In addition, non-Dairy ingredients like flavours, sugars, and fruits are also used in production and can add to the waste stream. The waste products from milk processing are mainly biodegradable, and standard treatment processes include both aerobic and anaerobic methods.

Oil and Fat Processing

The meat and poultry industries generate a variety of waste products, including those produced by the animals during livestock holding and high-strength wastes generated during processing. The processing stages include slaughtering, de-feathering or hide removal, eviscerating and trimming, washing, disinfecting, and cooling. Poultry plants, in particular, may process up to two million birds each week, making them significant waste generators on a large scale. The waste components consist of substantial amounts of nitrogenous organic compounds (proteins), fats, and inorganic compounds (nitrates).

pH of wastewater

Maintaining a specific pH level in food processing wastewater is crucial as it directly impacts the efficacy and effectiveness of different wastewater treatment methods. For example, if the pH level of the wastewater is too low or too high, it can affect the growth and activity of microorganisms used in biological treatment processes, such as activated sludge or anaerobic digestion.

Inadequate wastewater pH levels can also cause water acidity, potentially releasing acidic gases into the environment. These gases, including sulphur dioxide and nitrogen oxides, can harm human health, wildlife, and ecosystems. Not only can they produce acid rains, but if directly inhaled by employees, acidic gases such as sulphur dioxide (SO2), hydrogen chloride (HCl), and hydrogen fluoride (HF) can cause irritation and inflammation of the respiratory system, leading to coughing, wheezing, shortness of breath, and chest pain. Prolonged exposure to high concentrations of these gases can cause severe lung damage, including bronchitis, asthma, and even pulmonary oedema.

Conductivity of Wastewater

Conductivity refers to the ability of a substance to conduct an electric current. In wastewater management, conductivity is used as a measure of the amount of dissolved salts, minerals, and other inorganic compounds present in the water. These compounds can increase the water’s ability to conduct electricity.

If the conductivity of the wastewater is too high, it can lead to problems such as scaling and fouling of equipment used in the treatment process, such as pipes, filters, and membranes. Furthermore, high conductivity can also lead to the discharge of toxic metals and other harmful pollutants into the environment, adversely affecting aquatic life and the ecosystem.

Monitoring the conductivity of wastewater is an essential aspect of wastewater management, as it can help to identify sources of contamination and ensure that water treatment processes are working effectively to remove pollutants. Additionally, maintaining appropriate levels of conductivity in industrial wastewater can help to prevent damage to equipment and infrastructure that may be sensitive to high levels of dissolved solids.

DRAINSOL & DRAINGUARD

DRAIN GUARD, on the other hand, is a bio-engineered bacterial enzyme drain maintenance solution. The product combines fast-growing bacteria with a combination of enzymes that are effective in breaking down various substances that can cause blockages in drains, such as grease, fats, starches, proteins, cellulose, sludge, and vegetable matter. It also liquefies and digests these substances, maintaining free-flowing drains, pipes, traps, and septic systems.

DRAIN GUARD contains no pathogenic organisms, meaning it is safe to use and poses no health risk. The product is also environmentally friendly and does not contribute to pollution, as it contains biodegradable additives.

How to Use

DRAINSOL is a highly effective alkaline opener that dissolves fats, grease, and other substances that can cause drain blockages. Once you have used DRAINSOL for the initial cleaning, it is recommended to use DRAIN GUARD for daily maintenance. It’s vital to remember that cleaning the drains is crucial, especially if the clogging is severe (more than 50%). You can clean the drains through various methods such as vacuum suction, physical cleaning, or using products like DRAINSOL. After you have cleaned the drain and flushed it with clean water, you can fix the pump for automatic dosing of DRAIN GUARD. The recommended dosage is between 250-350 ml per day at a specific time.

ORAPI RECOMMENDS:

ORAPI RECOMMENDS:

Conclusion

In conclusion, effective wastewater management is a crucial aspect of the food processing industry to ensure compliance with regulations and minimise environmental and health risks. Food and agricultural waste can pose distinct challenges due to their biochemical oxygen demand (BOD) and chemical oxygen demand (COD) values, requiring careful consideration of unique factors. Drain lines, septic systems, and drain taps are critical components of wastewater management that regulate wastewater flow, separate wastewater streams, and ensure compliance with regulations. Treatment methods commonly used for treating wastewater from food processing include biological and physical-chemical treatments, oxidative and anaerobic processes, and in-plant recycling. The food processing industry must embrace sustainable solutions to tackle the growing challenge of wastewater management effectively.