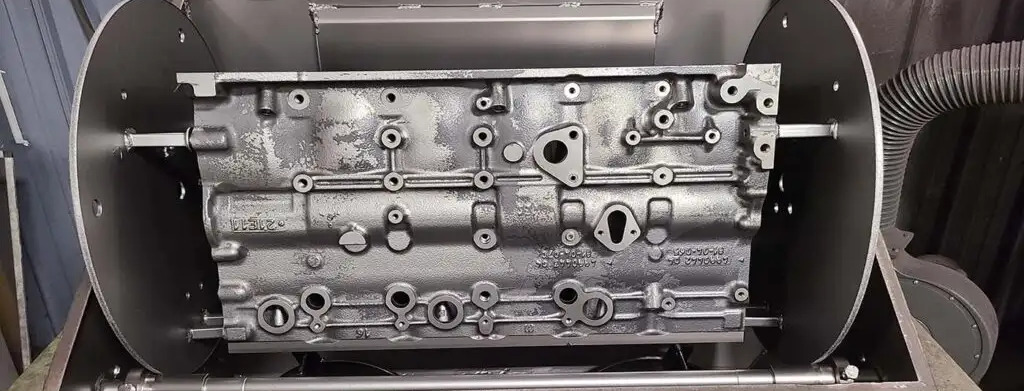

As water-based and solvent cleaners gain popularity, the debate for suitability for cleaning and degreasing increases. Choosing between these options is crucial for businesses in various sectors. In this article, we compare their properties, performance, costs, safety, and regulations to help you make an informed decision for your needs.

Water-Based and Solvent Cleaners Differences

Solvent Cleaners

ORAPI RECOMMENDS:

- ORANGE SOLVENT is a unique biodegradable solvent cleaner formulated from derivatives of orange oils and synthesized mineral oil with a flash point of 69°C.

- ORANGE SOLVENT replaces chlorinated and paraffin-based solvents in most applications, thus offering a safer alternative for effective cleaning.

Flammable Solvent Cleaners vs Non Flammable Solvent Cleaners

When considering solvent cleaners, the initial decision often revolves around choosing between flammable and nonflammable options. If conditions allow for the safe use of flammable solvents, with proper ventilation, absence of ignition sources, and adherence to safety protocols, they typically offer a cost advantage over nonflammable alternatives. However, if safety concerns such as inadequate ventilation or the presence of ignition sources arise, numerous nonflammable solvents are available as alternatives.

Divergent Evaporation Rates of Solvent Cleaners

Solvents exhibit diverse evaporation rates: some swiftly volatilize at ambient conditions, while others necessitate elevated temperatures for evaporation. Rapidly evaporating solvents minimise process downtime, whereas slower-evaporating counterparts are optimal for high-temperature soak applications. No single solvent universally suits all tasks. Additionally, slower-evaporating solvents tend to produce fewer volatile organic compounds (VOCs) but might require supplementary drying procedures.

Understanding Solvent Surface Tension

Surface tension, a fundamental property of liquids, quantifies their capacity to coalesce into cohesive droplets. Lower surface tension denotes a reduced tendency for the substance to form droplets, facilitating its spread and adhesion to surfaces, resulting in a uniform coating. Conversely, liquids with higher surface tension exhibit a propensity to form droplets. Typically, solvents exhibit lower surface tension compared to water-based cleaners, enabling them to penetrate confined spaces for effective soil removal without becoming trapped.

Safety Precautions Regarding Solvent Cleaners

Water-based Cleaners

Water-based cleaning solutions dissolve contaminants and chemically interact with them, rendering them more soluble in water. For instance, certain materials react more readily in an acidic environment (pH below 7), found in substances like lemons (citric acid), vinegar (acetic acid), carbonated beverages (carbonic and phosphoric acid), and car batteries (sulfuric acid). Conversely, some substances are more reactive or soluble in alkaline solutions (pH above 7), such as ammonia, bleach (sodium hypochlorite), lye (sodium hydroxide), and oven cleaners (which often contain sodium hydroxide).

Additionally, aqueous cleaners often include various components to improve their efficacy:

- Detergents or surfactants: These substances possess wetting and emulsifying properties, facilitating the dissolution of soils into the solution.

- Builders: These materials enhance the effectiveness of detergents by increasing the alkalinity of the solution.

- Emulsifiers help carry oils into water solutions, creating a liquid-in-liquid solution.

- Saponifiers: These substances react with fatty acids and carboxyl groups, forming water-soluble soaps that dissolve into the solution.

- Sequestering agents: These bind with metals like calcium, magnesium, and others found in hard water, which can hinder the cleaning process. Sequestering agents can bind with multiple metal ions simultaneously.

- Chelating agents: Similar to sequestering agents, they bind with individual metal ions.

While the combination of water, solvents, surfactants, and saponifiers can rival solvent cleaning in effectiveness, it often necessitates a change in the cleaning procedure. Rinsing with water-based chemistries becomes essential in precision applications where residue tolerance is minimal. Batch or in-line cleaning systems typically incorporate rinse and dry cycles to address these concerns.

Varied Attributes of Water-Based Cleaners

Water-based cleaners can match the cleaning efficacy of solvent-based counterparts, yet they exhibit distinct characteristics:

Evaporation

Unlike solvent cleaners, water-based ones operate within a narrower evaporation time range. While solvents can evaporate over milliseconds to months, water-based degreasers typically require active application, either cold or hot soak.

Temperature Range

Water-based chemistries clean effectively within a temperature spectrum from room temperature to approximately 80°C. This variability, while significant, pales in comparison to the wide range solvents offer, spanning below freezing to over 200°C.

Surface Tension

Water-based cleaners generally have higher surface tensions than solvents. Adjustments like temperature modulation, surfactant variation, and system enhancements can mitigate this limitation. However, for intricate spaces, solvents with lower surface tension excel at penetrating and evaporating.

Reactive Additives

Certain additives in water-based cleaners can react aggressively with diverse materials such as metals, plastics, or inks. Post-cleaning validation is crucial to ensure material compatibility, avoiding residual reactive agents that may induce defects like electrical leakage or coating irregularities.

Rinsing and Drying

Water-based systems typically involve more elaborate rinse and dry processes, particularly in vapor degreasing applications, to eliminate cleaner residues and dissolved contaminants.

Environmental Impact

Environmental concerns, governed by global, national, and local regulations, shape cleaner choices for manufacturers:

- Protocols like Montreal and Kyoto restrict substances like CFCs, HCFCs, and HFCs due to ozone depletion and global warming.

- Regulatory bodies like the EPA and state agencies enforce limits on personnel exposure to toxic chemicals.

- CARB mandates restrictions on smog-producing VOCs in cleaners for specific cleaning applications.

- Hazardous Air Pollutants (HAPs) regulations aim to mitigate pollutants known to cause environmental damage or health issues. While some solvents fall under this category, water-based chemistries generally do not.

- Priority Pollutant List, regulated by the EPA under the Clean Water Act, includes several solvents but excludes aqueous cleaning chemistries.

ORAPI RECOMMENDS:

- SUPA CLEAN is a powerful renovator, blend of balance surfactants, safe solvents and inhibitors.

- SUPA CLEAN liquefies and emulsifies grease, oil, grime and traffic films.

- SUPA CLEAN is formulated to bridge the gap between conventional hard surface cleaners and strong solvent systems.

Which Cleaning Chemistry Suits Your Needs Best

Conclusion: Water-based vs Solvent Cleaners

This article has examined their properties, performance, costs, safety, and regulatory aspects in the discourse between water-based and solvent cleaners. Empowering readers with knowledge facilitates informed decisions tailored to specific needs. Whether prioritising solvent speed or water-based environmental benefits, evaluating individual requirements is paramount. Amid regulatory pressures, a diverse range of options ensures both solvents and water-based cleaners remain viable. Expert assistance is available to help you select the ideal chemistry. Thus, this comparison concludes, welcoming further inquiries for tailored solutions.