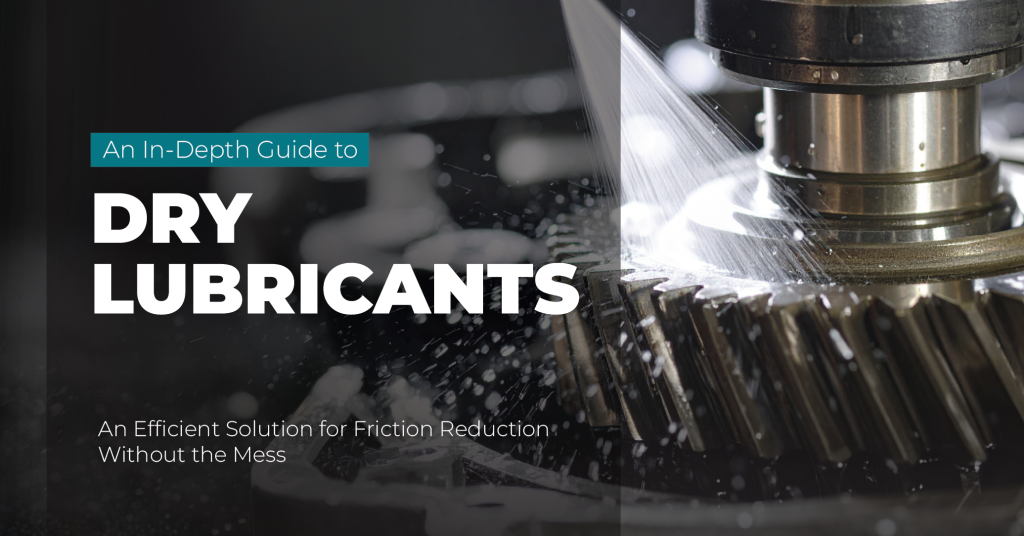

An In-Depth Guide to Dry Lubricants: An Efficient Solution for Friction Reduction Without the Mess

Discover the benefits, uses, and limitations of dry lubricants in this in-depth guide. Learn how dry lubricant offers efficient friction reduction without the mess of traditional oils.