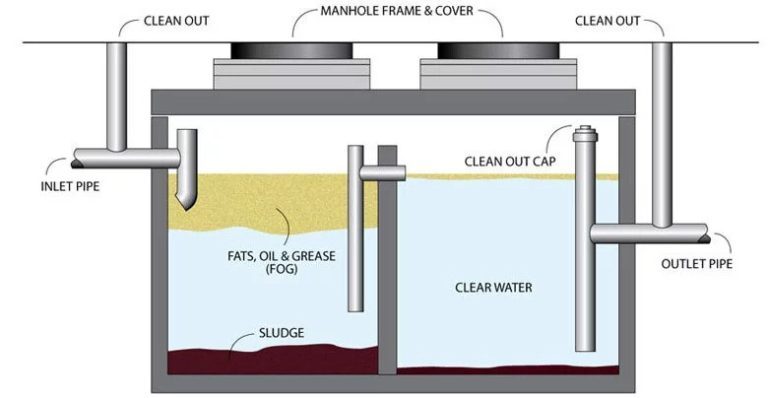

As global awareness of environmental concerns continues to grow, examining your FOG (Fats, Oils, and Grease) management presently can be a prudent investment, safeguarding your business against anticipated, increasingly stringent global legislation in the future. Grease traps are the central collection point for all fats, oils, and grease (FOGs). Neglecting their cleaning not only exposes you to regulatory consequences but also subjects you to substantial fines. This article covers everything related to grease traps for commercial kitchens: definition, types, and how to clean them. Keep reading to learn more about FOG management.

What Are Grease Traps for Commercial Kitchens

How Does a Grease Trap Work

ORAPI RECOMMENDS:

Types of Grease Traps for Commercial Kitchens

Three categories of grease traps include passive hydromechanical (manual), automatic, and gravity-based systems.

Passive Hydromechanical (Manual) Grease Traps

Automatic Grease Traps

Gravity Grease Traps

Cleaning the Grease Trap

Although cleaning grease traps may be an unpleasant task, it remains essential. The Environmental Protection Agency (EPA) reports that 47% of reported blockages in sewage systems are caused by FOG release. Regularly maintaining your trap can prevent your contribution to this issue and lower the chances of costly plumbing problems. Moreover, it eliminates unpleasant odours caused by accumulated FOG. Neglecting grease trap maintenance could lead to regulatory penalties and potential business closures due to violations of relevant laws and regulations.

Grease build-up serves as a significant cause of fires in restaurants. Neglecting the adequate cleaning and maintenance of your restaurant’s grease traps may result in fires, leading to substantial financial losses of thousands of dollars and hampering business operations.

Necessary Items

To ensure your safety and make the job easier, gathering the right gear before starting is essential. Rubber gloves will protect your hands, while a mask or nose plug will help you defend against odours. Protective coveralls are also important, along with a crowbar and wrench to lift the lid off of the grease trap. Additionally, you will need a scraper, a steel pot scrubber, dish soap, and a shop vacuum.

Locate and Assess

Guidelines for Cleaning Grease Traps

ORAPI RECOMMENDS:

Odourless Dishwashing Liquid

Rinse the soap and debris thoroughly several times using fresh water. This will result in a clean grease trap, which should be maintained every four to six weeks.

After completing the most strenuous aspect of the task:

- Assess your handiwork.

- Ensure that the grease trap is entirely free of FOGs and that there are no blockages impeding smooth water drainage.

- Proceed by draining a gallon of clean water from the kitchen sink.

Ensure unobstructed water flow through the grease trap. If a blockage is present, seek assistance from a licensed plumber to resolve it. Reassemble the components of the grease trap, such as the baffle and lid.

Disposal

Ensure appropriate disposal of accumulated fats, oils, and greases by placing them in double-lined garbage bags. If the quantity of FOGs is minimal, deposit them in the local dumpster. A pro-tip is to combine FOGs from the shop vacuum with kitty litter to solidify the grease particles before disposal. For substantial amounts of grease trap sludge, it is advisable to engage professional grease trap companies for proper disposal.

Things to Keep In Mind

Regular maintenance of grease traps is essential, ideally scheduling cleanings every four to six weeks. To extend the duration between cleanings, using bacteria additives (such as enzymatic cleaners) that naturally decompose waste can be beneficial. However, caution is advised against using hot water flushes or products containing only enzymes. These can liquefy FOGs (Fats, Oils, Grease), allowing them to flow into municipal sewer lines, causing potential issues. So, make sure your enzyme cleaner has a good mixture of enzymes and surfactants.

Conclusion: Grease Traps for Commercial Kitchens

In conclusion, proactive FOG (Fats, Oils, and Grease) management via grease traps is vital for food-related businesses amidst increasing environmental concerns and stringent regulations. From passive to automatic and gravity-based systems, Grease traps offer tailored solutions for diverse establishments. Regular maintenance, proper disposal, and use of recommended products like Drain Guard are crucial for preventing blockages, environmental hazards, and regulatory penalties. Adhering to maintenance schedules and employing enzymatic cleaners responsibly facilitates effective FOG control. Prioritising grease trap upkeep ensures compliance and mitigates operational disruptions, fostering sustainable business practices and environmental responsibility.