The fundamental principles of boundary and hydrodynamic lubrication are the two essential mechanisms for reducing friction and wear in mechanical systems. Proper lubrication is critical to maintaining machinery and reducing friction-related wear and tear. In this concise guide, we will explore the key differences between these two lubrication methods, delving into their distinct mechanisms, applications, and advantages. Understanding these different lubrication approaches empowers engineers to make informed decisions in selecting the right lubricant for optimal performance and durability in various industrial applications. Join us on this journey through the world of lubrication and uncover how these mechanisms play a vital role in maintaining smooth machinery operation.

The Two Types of Lubrication

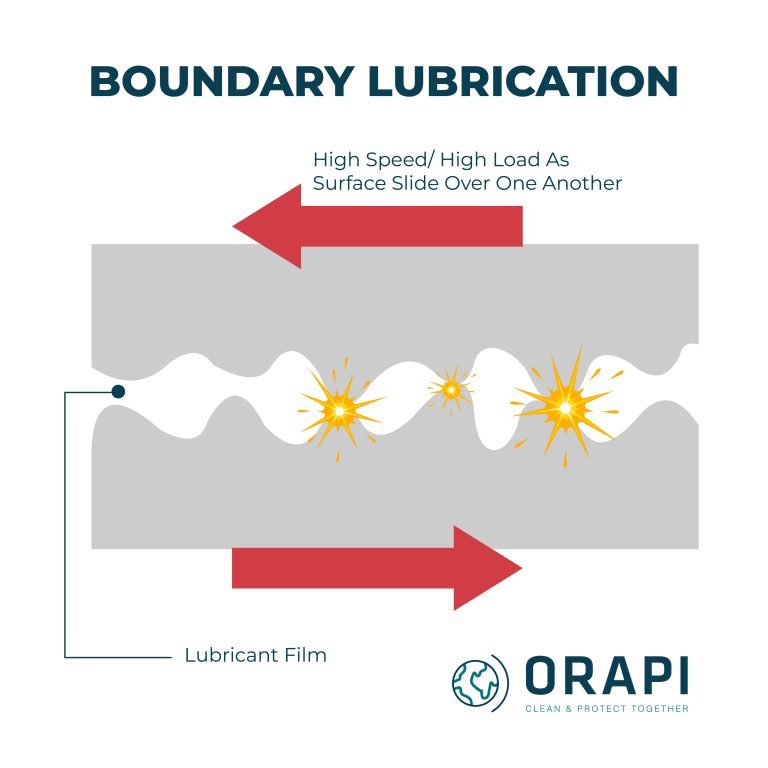

Boundary Lubrication (Solid/Chemical Lubrication)

Key Features of Boundary Lubrication

Thin Lubricant Film

The lubricant film in boundary lubrication is much thinner compared to hydrodynamic lubrication, and it may not fully prevent direct contact between the surfaces.

Low-Speed And/or Light-Load Conditions

Boundary lubrication is more common at low speeds or light loads where the pressure generated is insufficient to create a thick film.

Extreme Pressure Conditions

Boundary lubrication is prevalent in situations where extreme pressure or temperature disrupts the formation of a continuous thick film.

Solid Additives and Chemical Compounds

Boundary lubrication employs two main types of lubricants to prevent metal-to-metal contact:

Solid Lubricants

Solid lubricants are materials added to the lubricant to form a protective layer on the bearing surfaces. These solid particles can react or burnish against the surface asperities (microscopic hills and valleys) to create a wear-resistant surface. The solid additives act as a barrier between the two surfaces, reducing friction and wear.

Common examples of solid lubricants include:

- Molybdenum Disulfide: A grey-black solid lubricant that can withstand high loads and temperatures.

- Graphite: A form of carbon with excellent lubricating properties.

- PTFE (Polytetrafluoroethylene): Also known as Teflon, it offers low friction and high-temperature resistance.

- High-load white solids like talc: Used in specialised applications with high loads and extreme conditions.

Chemical Extreme Pressure (EP) Additives

Chemical EP additives are compounds added to the lubricant that react with the metal surfaces under high pressure or temperature to form a protective film. This film reduces friction and prevents wear.

Common examples of chemical EP additives include:

- Chlorine: In the form of chlorinated compounds, it can create a protective layer on metal surfaces.

- Sulphur: Often used as sulfurised compounds, it provides EP protection under extreme conditions.

- Phosphorous: Found in phosphorus-containing compounds, it enhances the lubricant’s ability to withstand high pressure.

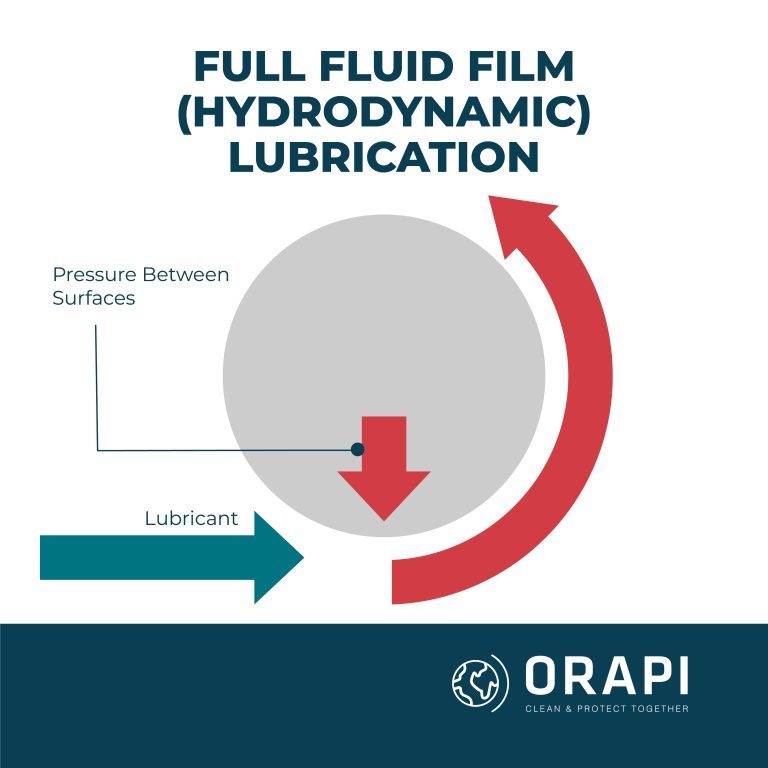

Hydrodynamic Lubrication (Liquid/Fluid Lubrication)

Key Features of Hydrodynamic Lubrication

Thick Lubricant Film

The lubricant layer is sufficiently thick to keep the surfaces separated and avoid direct metal-to-metal contact.

High-Speed And/or Heavy-Load Applications

Hydrodynamic lubrication is more effective in situations with high relative speeds or heavy loads, as these conditions generate the necessary pressure to maintain the lubricant film.

Fluid Viscosity

Viscosity is a property of liquids and fluids that defines their thickness or thinness. It quantifies a fluid’s resistance to flow. In the context of hydrodynamic lubrication, viscosity is crucial as it influences the lubricant’s ability to form and maintain the lubrication film.

Fluid Viscosity

Viscosity is not a constant property; it can change based on various factors. The key factors affecting viscosity are as follows:

- Temperature: As temperature decreases, the lubricant’s viscosity increases, making it thicker. Conversely, an increase in temperature reduces the viscosity, making it thinner.

- Pressure: An increase in pressure tends to increase the viscosity of the lubricant, making it more resistant to flow.

- Shear: Shear refers to the force applied parallel to the surfaces in motion. In hydrodynamic lubrication, shear decreases viscosity, making the lubricant more fluid-like.

- Time: Over time, the viscosity of the lubricant can change due to factors such as product quality or stability.

Viscosity Units

Viscosity is measured in various units. Two common units are:

- Dynamic Viscosity: Measured in Poise (symbol P). However, for practical purposes, we often use Centipoise (cP), which equals 1/100th of a Poise.

- Kinematic Viscosity: Measured in Stokes (symbol St). Centistokes (cSt) is a more commonly used unit equal to 1/100th of a Stokes.

Relationship Between cSt and cP: In many cases, the viscosity of a fluid in centistokes (cSt) is approximately equal to its viscosity in centipoise (cP).

Density: The ISO system uses centistokes (cSt) to directly translate the viscosity measurement into square millimetres per second (mm²/s).

Base Oils

Base oils are the primary components of lubricants that provide hydrodynamic lubrication. Different types of base oils are used depending on the temperature range of the application:

- Mineral Base Oils: Suitable for temperatures ranging from -30°C to 150°C.

- Synthetic Base Oils: Ideal for higher temperature applications, ranging from -70°C to 300°C.

Conclusion: Boundary vs Hydrodynamic Lubrication

In conclusion, real-world lubrication mechanisms often combine hydrodynamic and boundary lubrication. The effectiveness of the lubricant depends on specific operating conditions. Boundary lubrication, with additives or EP compounds, protects surfaces from wear and friction, making it ideal for extreme conditions. In contrast, hydrodynamic lubrication uses relative motion to generate a pressure wedge, reducing friction. Viscosity and temperature affect this process, guiding the selection of suitable base oils. In boundary lubrication, the friction force remains unaffected by the speed, whereas in hydrodynamic lubrication, the viscous friction force rises proportionally with increasing speed. Engineers and designers consider these mechanisms when choosing the right lubricant for each application.