Greases have widespread applications in diverse industries and are ideal for machines operating irregularly or where frequent oil changes are impractical. Nevertheless, the many grease variants available can make selecting the appropriate one challenging. When choosing a grease lubricant, several crucial factors merit consideration, including its base penetrability, NLGI grade, lubricating oil, thickener type, and additives. Emphasising grease consistency is vital in systems that require blending multiple grease lubricant formulations. ORAPI has meticulously curated the ultimate guide to different grease types and their respective applications to address this issue comprehensively.

Definition

Penetrability of Grease Lubricants (Grade-Physical Consistency)

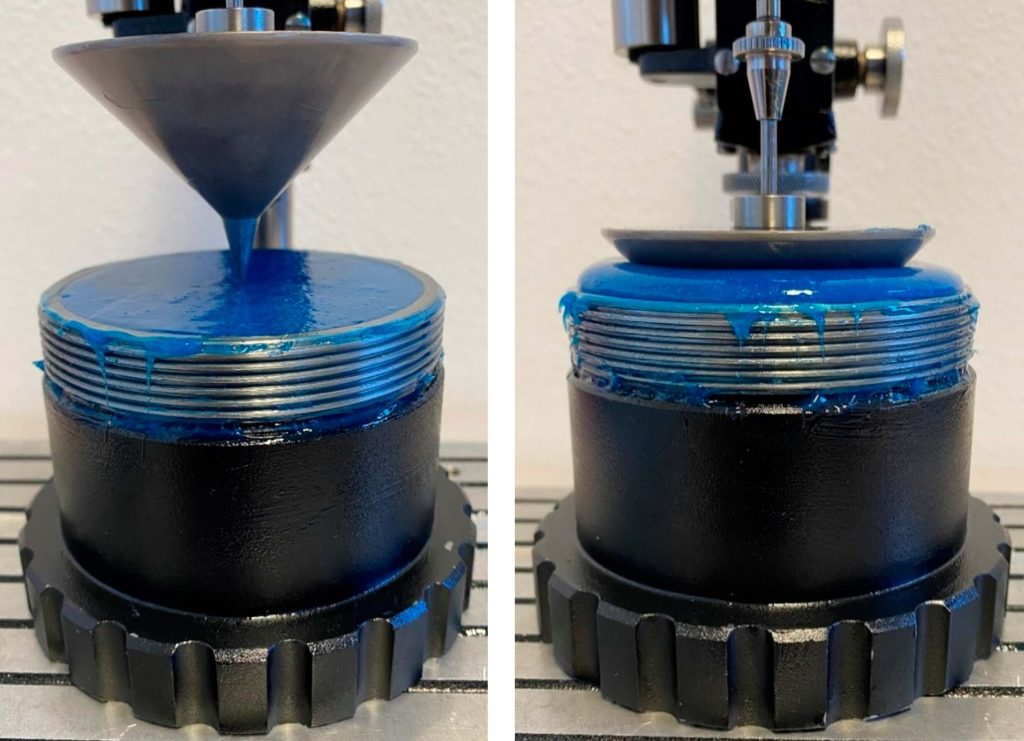

The penetrability of grease is a measure of its physical consistency. It involves dipping a cone into the grease lubricant to be tested & observing the penetration depth in tenths of millimetres (1/10mm). The variation in penetration between the non-worked and worked tests indicates the grease’s stability. In other words, it shows how the physical properties of the grease change due to mechanical action, which can be important in certain applications.

Penetrability on Unworked Grease Lubricants

Unworked penetration is determined by bringing a grease lubricant sample to a temperature of 25°C (77°F) and transferring it to a standard cup. The grease surface is then smoothed, and the penetrometer assembly, consisting of a cone and its movable parts weighing 150 grams (0.33 lbs.), is positioned so that the cone’s tip barely touches the grease surface.

After placing the assembly on top of the grease for precisely five seconds, the distance the cone drops and penetrates the grease is measured and recorded as the unworked penetration level.

Penetrability on Worked Grease Lubricants

Standardised Measuring Instruments

- Penetrometer: This device is specifically designed for measuring the penetration of the cone into the grease. It provides precise and repeatable measurements.

- Kneading machine: This machine works the grease lubricant mechanically, simulating the effects of shear stress and pressure that the grease might experience during use. The kneading process helps determine how the grease’s properties change after being subjected to mechanical forces.

Classification According to NLGI (National Lubricant Grease Institute)

The NLGI stands for the National Lubricating Grease Institute, an organisation founded in the United States in 1933. The NLGI is a non-profit trade association that sets standards, provides technical support, and promotes research on lubricating greases.

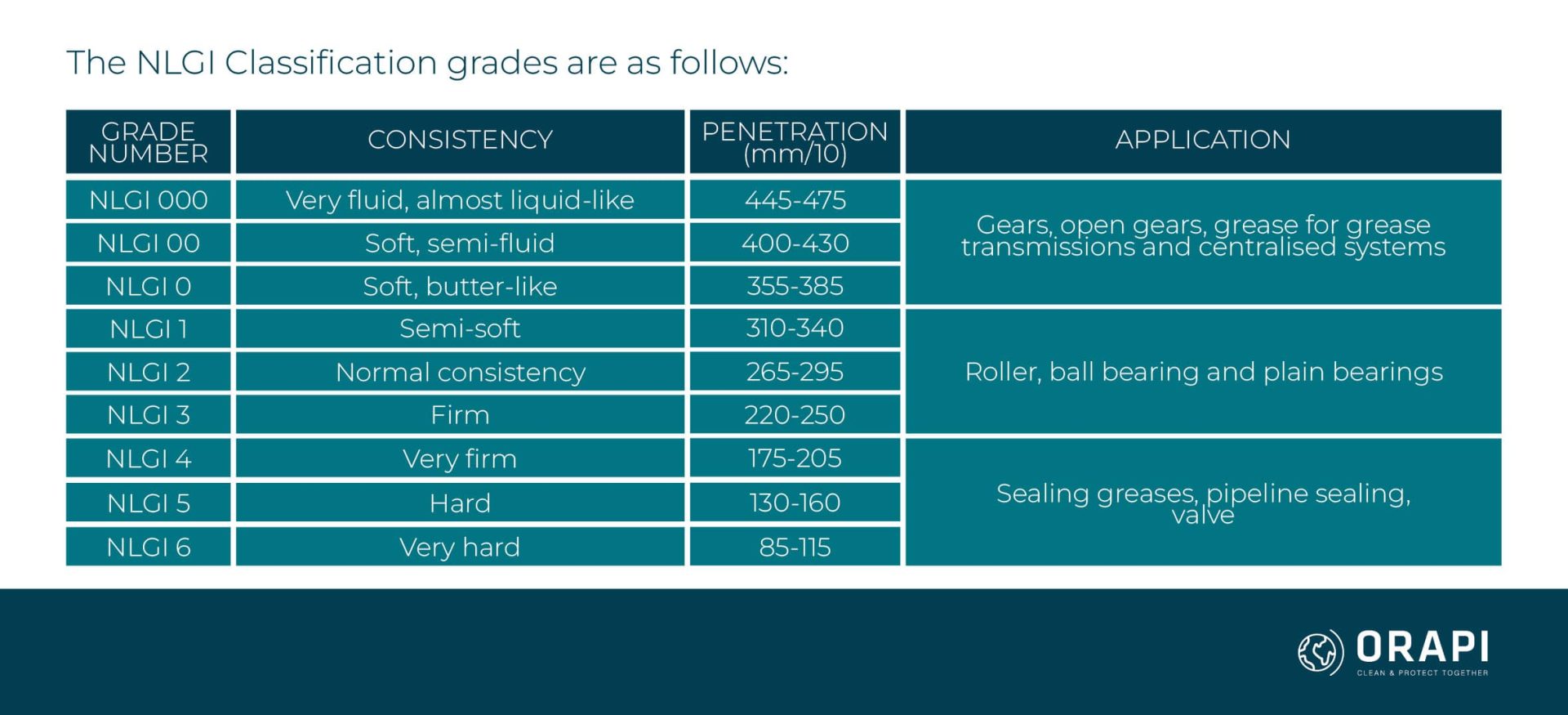

One of the most widely used and recognised standards established by the NLGI is the NLGI Classification, which categorises greases based on their consistency or hardness. The NLGI Classification uses a scale from 000 to 6 to define different grades of grease. The classification is based on penetrating a standard cone into the grease lubricant under specific conditions.

The NLGI Classification grades are as follows:

NLGI 000 – Very fluid, almost liquid-like consistency.

NLGI 00 – Soft, semi-fluid consistency.

NLGI 0 – Soft, butter-like consistency.

NLGI 1 – Semi-soft consistency.

NLGI 2 – Normal consistency, also known as “multipurpose” or “general purpose” grease.

NLGI 3 – Firm consistency.

NLGI 4 – Very firm consistency.

NLGI 5 – Hard consistency.

NLGI 6 – Very hard consistency.

The NLGI Classification is crucial because it helps users and manufacturers select the appropriate grease lubricant for specific applications based on the required consistency and performance characteristics. For example, greases with lower NLGI numbers (000 to 2) are often used in centralised lubrication systems or in applications where low friction is essential. In comparison, greases with higher NLGI numbers (3 to 6) are used in applications requiring high stability and mechanical stability.

It’s worth noting that the NLGI Classification is just one aspect of grease specifications, and other factors such as base oil type, thickener type, additives, and performance properties also play a significant role in determining the suitability of grease for a particular application.

Grease Drop Point

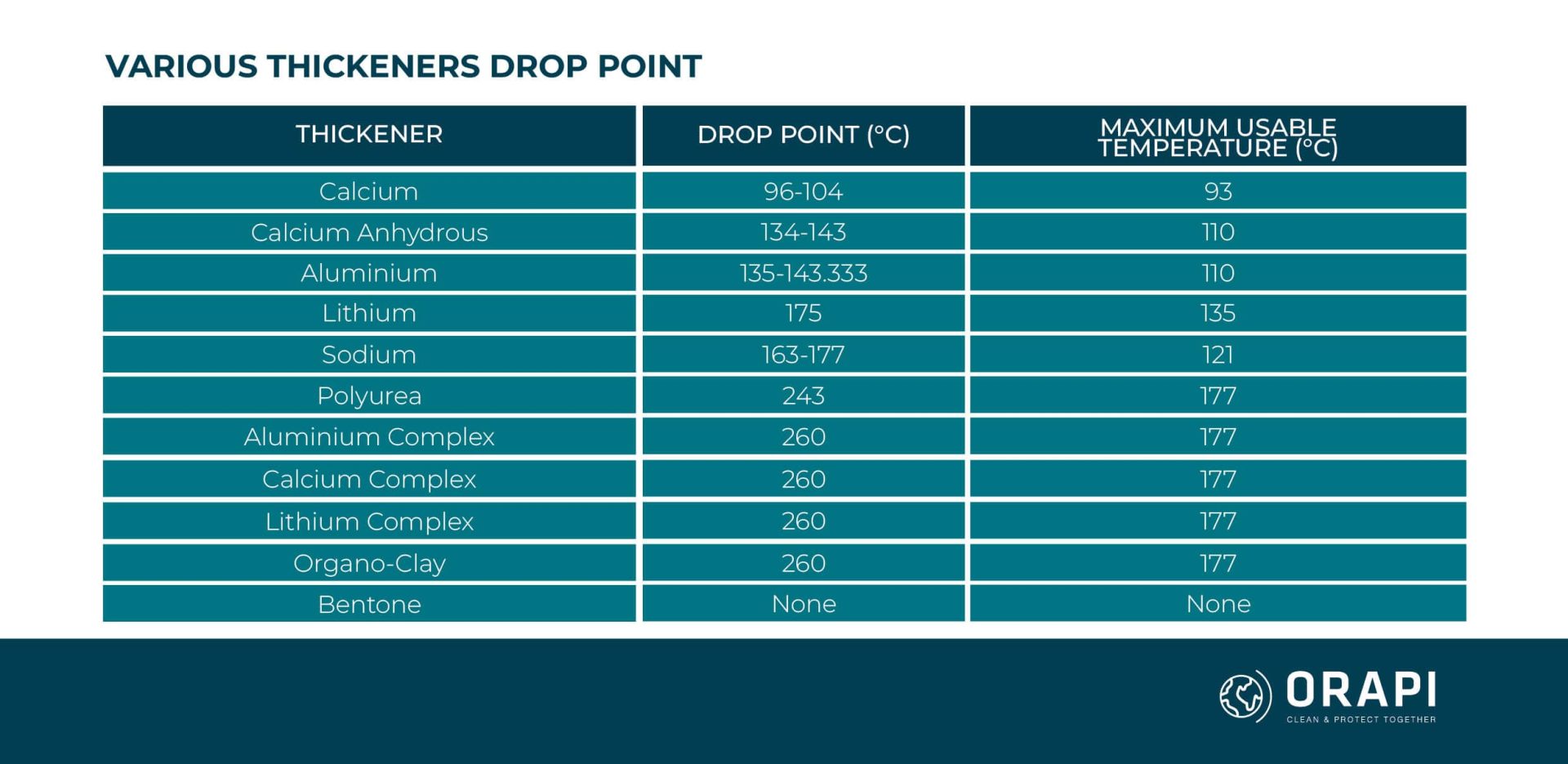

The drop point of grease is a crucial parameter used to assess the thermal stability of the grease. It is the temperature at which the grease transitions from a semi-solid or solid state to a liquid state as the thickener structure breaks down and the lubricating oil is released. This transition from a solid to a liquid-like state can be observed by the formation of a drop of oil falling from the heated grease.

Temperature at Which a Heated Grease Gives Out an Oil Drop

To determine the drop point of grease, a sample of it is heated under controlled conditions until the drop of oil forms and falls. The specific testing method may vary, but commonly, it involves heating the sample in a test apparatus, and the temperature at which the drop of oil separates is recorded as the drop point.

The Drop Point is Not the Maximum Temperature of Use

It’s important to emphasise that the drop point is not the recommended or maximum operating temperature for the grease. The drop point indicates the temperature at which the grease undergoes a physical change and starts to release oil. The grease should not be used continuously at or above its drop point temperature.

The Temperature Must Be 50°c Below

This part of the statement specifies a safety margin for the operating temperature of the equipment or machinery. It suggests that the operating temperature should be maintained at least 50°C below the grease’s drop point temperature.

dmN factor

“dmN factor” in the context of grease and bearing speed limitations.

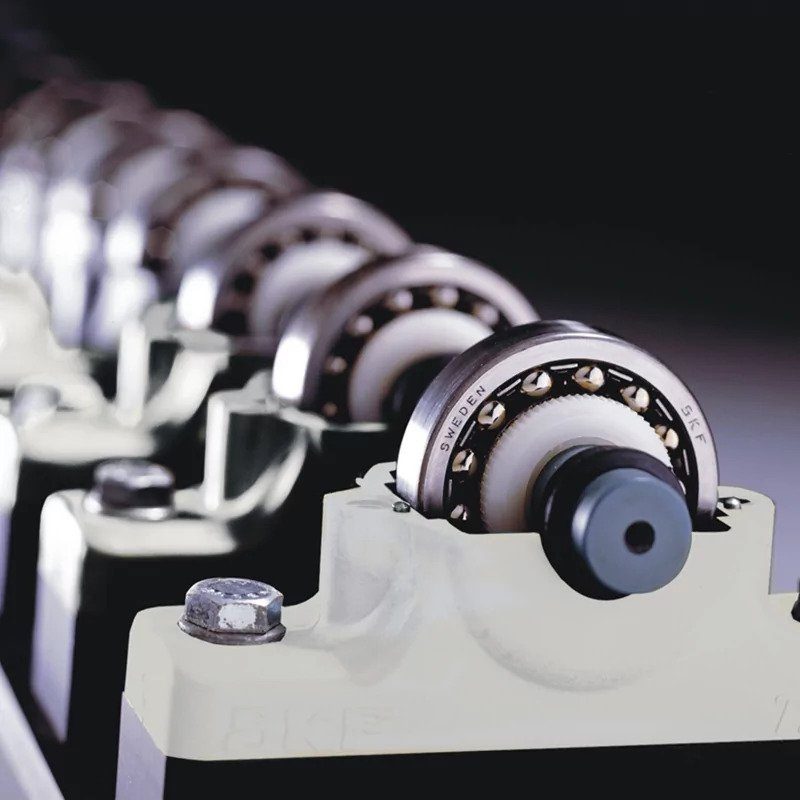

Bearing Speed Factor (dmN Factor): The dmN factor is a parameter used to assess the speed limitations of grease in a bearing application. Greases are used to lubricate bearings to reduce friction and wear. However, as the bearing rotates at higher speeds, the grease’s ability to maintain lubrication and prevent overheating becomes critical.

Formula to Calculate dmN Factor

The dmN factor is calculated by multiplying the bearing mean diameter (dm) in millimetres by the bearing speed (N) in revolutions per minute (rpm):

dmN = Mean Diameter (mm) x RPM

- Mean diameter (dm): The mean diameter (dm) is calculated using the following formula:

Mean Diameter (dm) = Shaft Diameter + Bearing Outer Race Diameter / 2

- dmN Factors for Different Bearing Types: Different types of bearings have different recommended dmN factors for optimal performance. The values are generally expressed as a fraction of the bearing mean diameter and rotational speed (dmN) product.

dmN Factors For Some Common Bearing Types

- Ball Bearings: dmN = Mean Diameter (mm) x RPM (This is the standard value, indicated as DN)

- Double Row Ball Bearings: dmN = 0.8 * Mean Diameter (mm) x RPM

- Tapered Roller Bearings: dmN = 0.6 * Mean Diameter (mm) x RPM

- Double-Row Tapered Roller Bearings: dmN = 0.7 * Mean Diameter (mm) x RPM

The dmN factor is an important parameter when selecting a grease for bearing applications. It helps engineers and maintenance professionals determine the appropriate grease to withstand the specific bearing speed while maintaining proper lubrication and preventing overheating. The dmN factors for different bearing types offer guidelines for choosing the right grease to ensure optimal bearing performance and longevity.

dmN factor

Grease is a lubricating material that reduces friction between moving parts in machinery. The testing methods described are used to assess the effectiveness of the grease in withstanding extreme pressure and minimising wear between components.

Extreme Pressure Properties Test

- Four ball bearings are immersed in the grease to be tested.

- Among these balls, the top ball is allowed to rotate.

- The test involves increasing the load until the ball’s welding occurs.

- Welding refers to a severe form of friction and heat generated between metal surfaces that causes them to stick together.

- If the welding load (the load at which the balls weld) is greater than 250 kg, then the grease is classified as “Extreme Pressure Grease.”

- If the welding load is equal to 160 kg, then the grease is categorised as “Normal Grease.”

Antiwear Properties Test

- The test involves subjecting the grease to a constant load of 40 kg for 1 hour.

- After the test period, the “print” or impression left by the ball on the surface of the grease is examined.

- The diameter of the print is measured.

- The smaller the diameter of the print, the better the antiwear power of the grease.

- In other words, a smaller print indicates that the grease has better resistance to wear, which is desirable for the longevity and efficiency of machinery.

These tests are essential for evaluating the performance of different types of grease and selecting the most suitable one for specific applications where extreme pressure and antiwear properties are crucial factors. Grease with higher intense pressure and antiwear properties is preferred in heavy-duty applications where machinery operates under high loads and requires excellent protection against wear and friction.

Protection Against Corrosion Test

Grease is crucial in protecting against corrosion in various mechanical systems and components. One of the standard tests used to evaluate a grease’s ability to resist corrosion is the SKF EMCOR test. This test involves subjecting a load-bearing apparatus, typically a bearing, to a specific environment for eight days, where the grease is exposed to water or seawater during alternating on and off periods.

The test procedure typically goes as follows:

- Load Bearing Setup: A load-bearing test apparatus, such as a bearing, is selected for the test. This component is representative of the equipment where the grease will be used in real-world applications.

- Grease Application: The grease under evaluation is applied to the load-bearing component. The quantity and method of application are carefully controlled to ensure consistency across different tests.

- Exposure to Water or Seawater: The load-bearing apparatus, with the applied grease, is exposed to a controlled environment containing freshwater or seawater. Water, especially seawater, is known to accelerate corrosion processes due to its higher salt content.

- Alternating On/Off Periods: During the test, the load-bearing component experiences alternating on and off periods. This means that the component is in operation for a certain period and then switched off for another period, replicating real-world conditions where machinery may go through cycles of operation.

- Rust Print Examination: After the 8-day test period, the load-bearing component is carefully examined for signs of corrosion. A rust print is typically taken from the component’s surface, and its extent and appearance are analysed.

- Determining Resistance to Corrosion: The analysis of the rust print provides crucial insights into the grease’s ability to protect the load-bearing component against corrosion. If the grease effectively resisted corrosion, the rust print would be minimal or absent, indicating that the surface of the load-bearing element remained relatively free from rust.

The SKF EMCOR test helps manufacturers and engineers select the right grease for specific applications where corrosion protection is critical. Corrosion can significantly affect the performance and lifespan of machinery and equipment, leading to costly maintenance and repairs. Greases that perform well in this test are preferred for use in marine environments, outdoor equipment, and any other application where exposure to moisture is a concern.

It’s important to note that while the SKF EMCOR test is a valuable tool for assessing a grease’s corrosion resistance, it is just one of many tests and factors considered in selecting the most suitable grease for a particular application. Other properties such as load-carrying capacity, temperature resistance, and shear stability also play important roles in determining the overall performance of grease in various applications.

Composition of Grease Lubricants

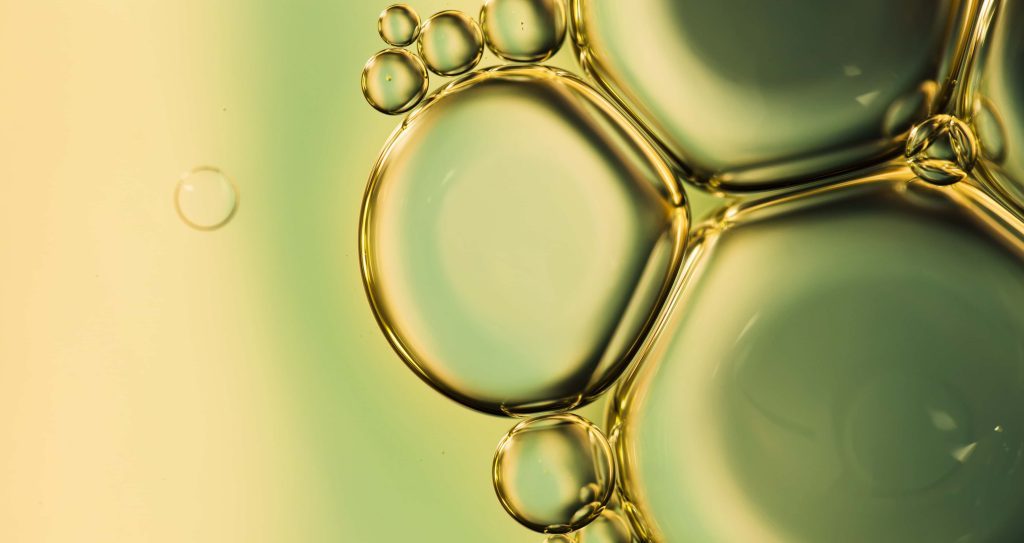

Grease is a lubricant commonly used to reduce friction between moving surfaces in various mechanical applications. Its composition is crucial in determining its performance and suitability for specific uses. Grease typically comprises three main components: lubricating oil, thickener, and additives.

Lubricating Oil (80-90%)

Lubricating oil is the base fluid in grease, comprising most of its composition. It provides lubrication between surfaces, reduces friction, and prevents wear and tear. The choice of lubricating oil is critical as it determines the grease’s temperature range and viscosity characteristics. Different types of lubricating oils are used based on the operating conditions and requirements of the application.

Thickener (5-10%)

The thickener is a key component that gives grease its semi-solid consistency. It acts as a sponge or matrix to hold the lubricating oil in place, preventing it from leaking or dripping from the application site. The thickener is usually a complex soap or synthetic material that provides structural stability to the grease. Common thickener types include lithium, calcium, polyurea, and aluminium complexes, among others.

Additives (0-10%)

Additives are optional components in grease, but they can significantly enhance its performance and provide specific properties tailored to the application’s needs. The percentage of additives may vary based on the desired characteristics of the grease. Some common additives include anti-corrosion agents, extreme pressure additives to handle high loads, antioxidants to prevent oxidation, and anti-wear additives to extend the lifespan of components.

One of the significant advantages of grease over liquid lubricants (such as oil) is its mechanical stability in dynamic applications. Due to its semi-solid nature, grease stays in place and adheres well to surfaces even under motion or vibration. This ensures a continuous and reliable lubricating film between moving parts, reducing friction, and preventing damage caused by metal-to-metal contact. Therefore, greases are suitable for movement applications, such as automotive wheel bearings, industrial machinery, and other mechanical systems.

In the subsequent part of this article, we will explain lubricating oils, thickeners, and additives in-depth and tell you exactly how these components influence grease characteristics.

Conclusion: Understanding The Basics of Grease Lubricant

In conclusion, grease is a vital lubricating material, reducing friction and wear in mechanical applications. Its physical consistency, measured by penetrability, influences stability and effectiveness. The NLGI Classification offers a standardised scale for selecting suitable grease lubricant. The drop point indicates thermal stability, preventing damage due to temperature extremes. Engineers must keep operating temperatures at least 50°C below the drop point. The dmN factor is crucial for proper bearing lubrication at different speeds. Various tests evaluate extreme pressure, antiwear properties, and corrosion resistance. Grease composition, including lubricating oil, thickener, and additives, impacts performance. Understanding these factors ensures optimal grease selection for mechanical applications, enhancing efficiency and longevity. Subsequent parts will delve deeper into lubricating oils, thickeners, and additives’ influence on grease characteristics.