Causes of Corrosion on Landing Gear Assemblies

Corrosion is the primary threat to any airframe assembly—without question. It’s often considered the most dangerous enemy of an aircraft because while components like engines or environmental systems can be replaced, corrosion spreads like cancer throughout the entire airframe.

In essence, four key elements must be present for corrosion to occur:

- Anode: A metal prone to rusting, typically steel in aircraft.

- Cathode: A dissimilar metal that’s less likely to corrode, such as aluminum or a protected part of the same metal.

- Electrolyte: A conductive liquid that allows ions to move between the anode and cathode—usually water.

- Electrical contact: An electrical connection between the anode and cathode.

Environmental Factors Responsible

The previous explanation simplifies the complex nature of corrosion. Aircraft operate in extreme conditions, and various environmental factors significantly impact how quickly corrosion develops. For example, seawater accelerates corrosion up to 1,000 times faster than tap or distilled water. To combat this, the Air Force follows a standard washing schedule, with aircraft near coastal areas being washed six times more frequently than those stationed inland.

Stresses Common to Landing Gear

Cleaning the Landing Gear

Cleaning Methods for Landing Gear

Pre-Saturated Wipes: A Safer Option

A safer and more effective alternative is to use pre-saturated wipes. These wipes evaporate quickly and reduce the risk of cross-contamination since they are disposable. Simply wipe down the struts, wheels, and other components, and discard the wipe when finished. By using this method, you can reduce the risk of contaminating tires or brakes with hydraulic fluid, while effectively degreasing landing gear components.

Maintaining Chrome on Struts

Clean the chrome frequently to keep the struts in good condition. Dirt and grime can build up, potentially causing seals to malfunction and leading to hydraulic leaks. This could result in a strut fully deflating, requiring you to deflate and reinflate all struts to maintain balance, which is a time-consuming process. To prevent this, it’s crucial to wipe down the chrome before refueling to stop grime from reaching the seals as the aircraft settles.

Non-Flammable Degreaser: Keeping Chrome Spotless

Using a non-flammable aerosol degreaser is an excellent solution for cutting through grime, keeping seals intact, and maintaining clean, spotless chrome.

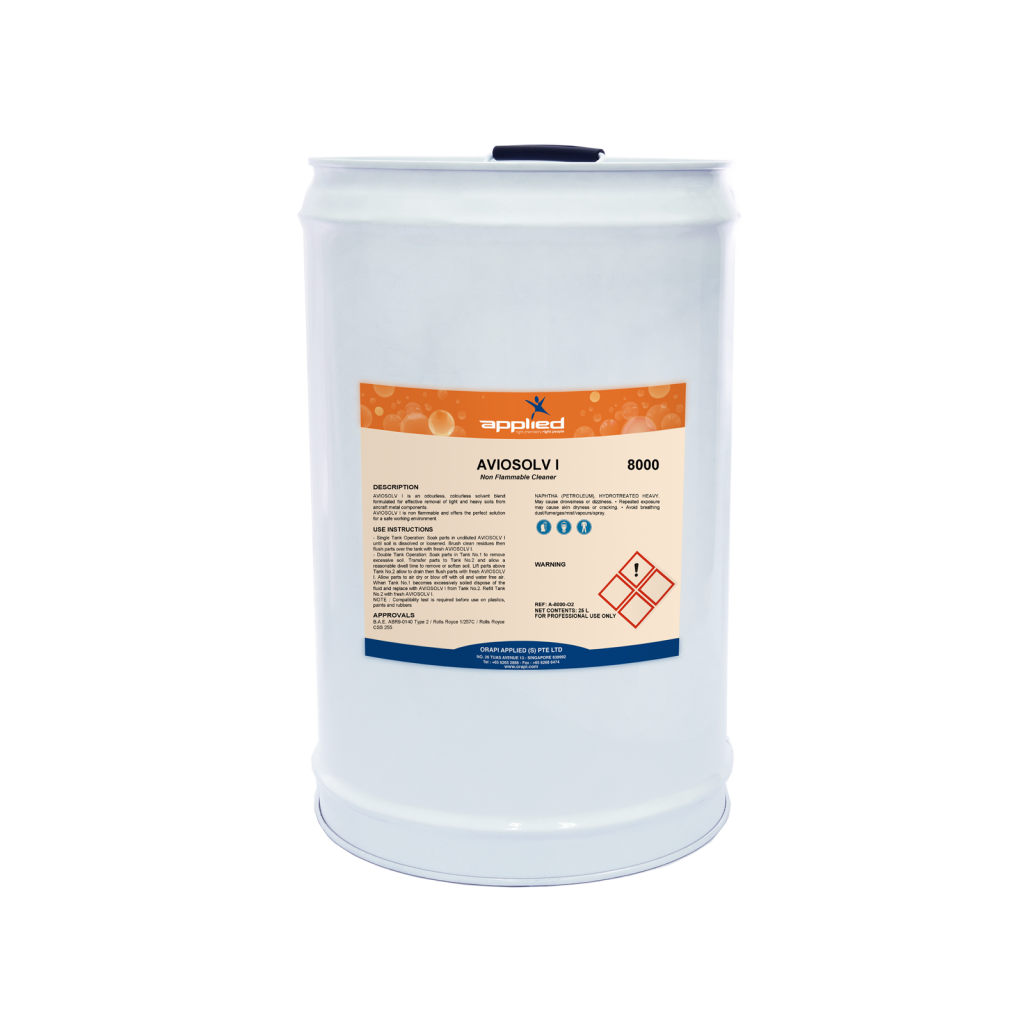

ORAPI RECOMMENDS:

AVIOSOLV I is an odourless, colourless solvent blend formulated for

effective removal of light and heavy soils from aircraft metal components.

AVIOSOLV I is non-flammable and offers the perfect solution for a safe working environment.

Conclusion

In conclusion, degreasing landing gear, is vital for both aesthetic appeal and operational safety. Regular cleaning helps prevent corrosion, which poses a serious threat to the integrity of an airframe. By using safer and more effective cleaning methods, such as pre-saturated wipes and non-flammable degreasers, aircraft maintenance teams can enhance inspection accuracy and prolong the lifespan of key components. A well-maintained aircraft not only ensures smoother operations but also safeguards against hidden mechanical failures that could compromise flight safety.

Complete list of Aircraft MRO + Cleaning Products under 1 Download