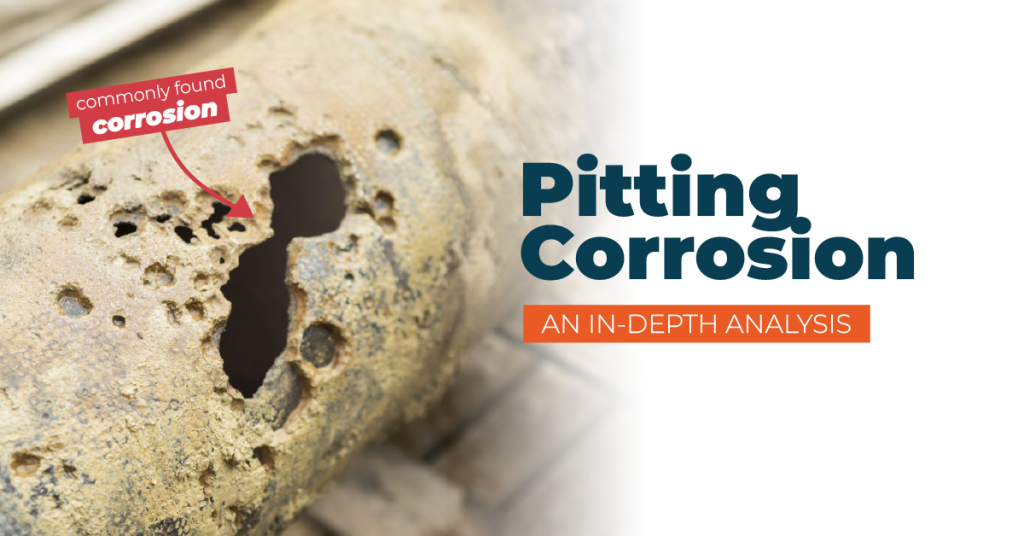

Pitting Corrosion: An In-Depth Analysis

What is Pitting Corrosion? Pitting corrosion is a specific type of corrosion that creates cavities or “holes” within a material. It is more perilous than uniform corrosion because it’s challenging to detect, predict, and safeguard against. Corrosion products frequently conceal these pits, and even a small, narrow pit with minimal metal loss can trigger failure in an entire engineering system. Pitting corrosion, a common factor in various localised corrosion attacks, can manifest in diverse shapes. These pits may appear open