Keeping manufacturing equipment clean and safe is critical in the food industry. This is where Cleaning in Place (CIP) systems come in handy. A CIP system includes various components such as steam, water, electricity, drain access, and air, and the cleaning process involves balancing the right chemical, temperature, time, and action to achieve the desired results. In part 2 of our CIP series, we will delve into the anatomy and principles of CIP, the CIP cleaning cycle, and the importance of using appropriate chemical solutions to avoid risks. Additionally, we will explore ORAPI Solutions, a provider of highly effective cleaning solutions for the food industry, and their approach to keeping equipment clean and compliant with regulations.

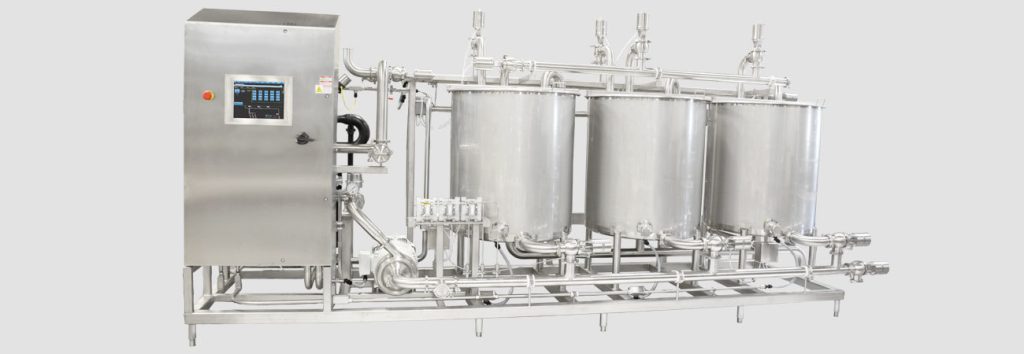

Anatomy of a CIP System

The anatomy of a Cleaning in Place system typically includes tanks, pumps, spray devices, heating systems, piping and valves, control instrumentation and automation. To provide a clear understanding, we have included a schematic diagram of a typical CIP system. It’s important to note that while the basic anatomy remains consistent, the dimensions may vary from one manufacturing facility to the next, depending on factors such as factory size and production requirements.

Utility Components of a CIP System

The fundamental elements of a Cleaning in Place system are straightforward and relatively easy to comprehend, drawing on the basic principles of cleaning.

Steam: Hot water requires steam.

Water: Clean and potable water is essential. Issues with water treatment are often the cause of microbiology problems.

Drain Access: To effectively remove the cleaning water and chemicals, drain access is crucial.

Electricity: Proper control of electricity to maintain pipeline temperature is important to avoid Cleaning in Place performance issues caused by voltage fluctuations.

Air: Clean and compressed air is needed for drying the pipeline.

Ensure that components such as steam, water, and air are kept clean.

Principles of Cleaning in Place

The Key to Effective Cleaning: To get the cleaning job done right, whether it be floors, tanks, or pipelines, it’s important to be familiar with the Sinner Circle. This concept, which involves balancing the right temperature, action, chemical, and time (TACT), is the cornerstone of successful cleaning. To deepen your understanding, we recommend reading the article “The Role of Sinner’s Circle in Cleaning Performance“. By grasping the importance of the Sinner Circle, you’ll have a comprehensive understanding of the Cleaning in Place cycle.

The Cleaning in Place Cycle

1. REMOVAL

Push out the product remaining in the pipeline from before, so the pipeline has to be clean of any product residue before you can proceed to step 2.

2. PRE-RINSE: Removes Remaining Residue in Product Lines

Pre-rinse as an additive measure to make sure that no debris is left from the previous product.

3. CAUSTIC WASH

High pH Concentration

Caustic wash is done to thoroughly clean the pipeline. Now, because caustic wash has elevated the pH you must rinse to bring the pH down. And we would like to reiterate here that you must only rinse with clean, portable water.

4. INTERMEDIATE RINSE

Flushes Out Traces of Detergent From Caustic Wash

However, even after washing with an alkaline product you might have scales or rust remaining inside the equipment, and as most of you might already know alkaline products are not effective at getting rid of these residues. Therefore, you must follow the rinse with an acidic wash.

5. ACID WASH

Dissolves Mineral Scales From Hard Water Deposits and Protein Residues

Rinse again to neutralise the acidic product in the pipeline. This is where you introduce the air blowing to dry the inside of the equipment. Because you don’t want to leave any remnants of acid or water to make sure it is not only completely dry but also clean.

6. FINAL RINSE

Flushes Out Cleaning Agents to Drain Until Reclaim Conditions Are Met

This step is done to flush out any remaining traces of acid in the equipment. If the final rinse does not precede the sanitising rinse then it can cause the equipment to corrode which will eventually lead to the formation of pitts, ultimately leading to grave consequences which we will discuss further in the upcoming sections.

7. SANITIZING RINSE

Helps Kill Microorganisms Before Next Production Run

The last but definitely not the least is sanitising. It is worth noting here that many people prefer sanitising with hot water but with the rising energy crisis the cost of hot water is on the rise. But fret not because we have the perfect sustainable solution to this problem. Just keep reading to learn more.

It’s crucial to keep in mind that these are the basics of Cleaning in Place which was devised more than half a decade ago and since these measures have worked so well for so many decades, many companies still rely on them.

Chemical Solutions

It’s crucial to be aware that relying solely on pure caustic or pure acidic solutions can have detrimental effects on the pipeline. The surface will start to etch, resulting in the formation of pitts, which will eventually corrode and cause rust. In just a matter of months, noticeable etching can occur, and prolonged exposure can lead to thinning and eventually rupture of the pipeline.

The consequences of using pure alkaline or acid solutions in Cleaning in Place systems are severe, not only causing efficiency-loss when the damaged pipelines have to be shut down but also putting employees at risk in the event of a pipeline burst, which can cause them harm by exposing them to chemicals.

Chemical Solutions Elaborated

At the outset, we outlined 8 critical steps, however, with a thorough understanding of the functioning of the Cleaning in Place system, we can simplify it to 5 fundamental steps: pre-rinse, washing with caustic, acid wash, application of sanitizer, and a thorough rinse.

We cannot stress enough the importance of using potable water instead of tap water in the Cleaning in Place process. Using untreated or underground water can introduce further issues to the equipment.

In terms of caustic solutions, sodium hydroxide (NaOH) and potassium hydroxide (KOH) are used to dissolve and eliminate organic residues, such as yeast and hops in breweries, oil from various production processes, and oil from milk production factories. The ideal temperature for using caustic solutions is 85°C, but for less oily products, a temperature of 35°C can also be used. However, to effectively clean equipment producing oily products, higher temperatures are necessary.

When it comes to acid solutions, hydrochloric acid (HCl), phosphoric acid (H3PO4), and peracetic acid (CH3CO3H) are common components. These acids are efficient in removing inorganic substances like beer stones.

Disinfectants, such as chlorine dioxide (ClO2), ozone (O3), and hydrogen peroxide (H2O2), are also essential in the CIP process. These chemicals are used to kill bacteria, fragments, and tough microorganisms that may survive the caustic wash. Such bacteria, such as clostridium botulinum, can survive temperatures up to 121°C and, if not removed, can contaminate the next batch of food, causing food poisoning. It is worth mentioning that combining acids with disinfectants can result in a highly effective solution and save time.

Finally, it is important to rinse away any chemical residues with water to reduce the risk of hazards in the factory. Residues from products can not only harm employees who come into contact with them but also damage the equipment if it is put into production without being fully rinsed. Moreover, skipping the final rinse step can result in undetected residues inside the equipment.

ORAPI Solutions

SPECTRUM 5923

ORAPI RECOMMENDS:

Spectrum is a highly effective alkaline detergent designed for the purpose of removing carbon deposits, rust, and grease from various surfaces. It can effectively clean burnt oils, fats, and rust on production equipment such as tanks, centrifuges, piping, grills, ovens, and cooking apparatus used in the food industry. Essentially, this product is capable of cleaning almost anything that needs to be cleaned.

BENEFITS OF USING SPECTRUM

Halal-Certified

The primary advantage of using this product is its halal certification, which is a rare feature among CIP products. This makes it a crucial consideration for various food products such as chilli sauce, ice cream, and drinks.

NSF Certified

Our product is NSF certified and easily traceable on the NSF whiteboard. So using SPECTRUM will not only showcase your establishment's commitment to safety and quality but also boost your customers’ confidence in both your products and your claims.

Hard Water Compatible:

Hard water is a common problem in Asia, ranging from 30 ppm to 1000 ppm. But with Spectrum, you can use it in both hard and soft water, making it a highly effective solution.

Low-Foaming:

The low-foaming property of Spectrum means less water usage and a reduced impact on your wastewater treatment plant. This leads to lower costs for utilities such as water and wastewater chemicals, and saves you time in the process.

Meets Food Contact Regulations:

Steel is a common feature in food processing units, but even those without stainless steel can still benefit from using Spectrum. It is safe for use on steel, stainless steel, and cast iron surfaces, ensuring compliance with regulations for food contact.

APPROVAL / CONFORMANCE C9664 DIRECTIONS FOR USE

As heavy duty alkaline cleaner: SPECTRUM should be used in a hot bath.

Concentrations of 0.3 – 0.4% for light deposits and rust at 85-90°C.

Concentrations of 0.4 – 0.8% for heavy duty cleaning & rust deposits at 85-90°C.

ACID PERAXOPHOS 2681

ORAPI RECOMMENDS:

A Low-Foaming, Non-Fuming Solution: This product is a combination of phosphoric acid, hydrogen peroxide, fat solubilizers, surfactants, and water hardness control agents.

Designed for Single-Stage Cleaning and Sanitation: ACID PEROXAPHOS 2681 can streamline the cleaning and disinfection process by combining both steps into one. So after washing with ACID PEROXAPHOS you can directly move on to the final rinse step. It saves time and improves production efficiency.

Efficiently Removes Inorganic Deposits: When the issue of biofilm becomes persistent and cannot be resolved, factory managers often resort to replacing their equipment. However, this can be costly as stainless steel equipment can be quite expensive, leaving a dent in their budget. Fortunately, ACID PEROXAPHOS is effective in removing inorganic deposits such as calcium oxalate (beerstone) and calcium phosphate (milkstone), as well as protein films, making it an effective solution for all issues related to CIP cleaning

Safe for a Wide Range of Materials: This product can be used on a variety of materials commonly found in food processing equipment, including stainless steel, dairy white metal, copper, brass, tin, Buna-N, and neoprene. It’s also safe for use on aluminium equipment within specific concentration-exposure-temperature limits and doesn’t emit any harmful fumes or odours.

MORE BENEFITS OF USING ACID PERAXOPHOS

- ACID PEROXAPHOS 2681 is also NSF and Halal certified

- Fast acidic cleaning step due to its excelling wetting properties because it contains phosphoric acid

- Powerful long-lasting sanitising action.

- Effective on most heat precipitated and hard water scale.

SANITISER DESTINY 3300

ORAPI RECOMMENDS:

DESTINY 3300 is a Versatile wide-spectrum disinfectant based on quaternary ammonium compound (QAC), for cleaning and disinfection of surfaces in food processing, dairy and beverage industries.

It provides superior protection against a wide range of microorganisms including gram-positive and gram-negative bacteria, yeasts, moulds, fungi, and algae. In fact, if a disinfectant without rinsing is desired, a solution of 4.88ml of DESTINY per 2.5L of water, with approximately 200 ppm QAC, can be used.

In comparison to peracetic acid, which is known for its strong odour, DESTINY 3300 is completely odourless.

MORE BENEFITS OF USING DESTINY

- Colourless

- Cost-effective

- Extremely fast acting

- Completely safe to use on food contact surfaces

- Effectively kills micro-organic growth at very low concentrations

- Non-toxic

- Non-corrosive

- Stable during storage and in use

For those who prefer to include a disinfection step after their acid rinse, DESTINY 3300 is available as an option. But for those who do not require it, they can use the effective combination of SPECTRUM 5923 for their caustic wash and ACID 2681 for their acid wash. These two solutions are sufficient in providing a thorough clean.

Pro Tip From ORAPI

Though many prefer to use peracetic acid to clean their Cleaning in Place equipment it is worth noting that peracetic acid is the combination of hydrogen peroxide and acetic acid, which causes it to emit a strong vinegar-like odour and if you use it to wash your CIP equipment that is used to produce food and beverage such as beer, soy sauce, chilli sauce, etc., not only will it ruin the taste of the product but it will take you forever to eliminate the pungent smell of the peracetic acid combined with the smell of the food.

Technical Support Provided by ORAPI

We understand that our customers require more than just products. As solution providers, we offer comprehensive after-care services to ensure that our customers are fully satisfied with their purchases. Whether you need assistance with microbiology pitts or want a demonstration of one of our products, our team is always on hand to provide support. Trust ORAPI to go above and beyond in providing you with the best solutions possible.

Why Trust ORAPI’s Cleaning in Place Solutions?

Consistent Formula

We have maintained a consistent formula over the years which is why several of our customers have placed their faith in our products and services for many years

Economy for CIP Systems

As we explained before, our products not only help you enhance your productive output but also help you save time.

Expert Technical Support:

Our team of experts is available to provide technical and informational support to all our customers.

Certified For Safety:

Our products are certified by ISO, HALAL, NSF and other organisations, ensuring that they are not only effective, but also safe for use in different environments, giving the public the peace of mind that we and our customers use trusted standards.

Easy Access to Information

All the information you need about our products, including Technical Data Sheets (TDS) and Safety Data Sheets (SDS), is available on our website, orapiasia.com, making it easy to access and learn more about the products you're interested in.

Cleaning In Place Validation

To meet the hazard critical control points (HACCP) you can conduct Cleaning in Place validation in the following three methods:

- TITRATION METHOD: is also known as neutralisation. So, if your product final is neutral then you know that it is clean.

- ATP RAPID TEST – PROPER METHODOLOGY: The benefits of ATP is that it will detect anything on a surface including chemical, bacteria, and soils except virus. Therefore, on the downside ATP reading can be very subjective.

- CONVENTIONAL MICROBIOLOGY –IN HOUSE, EXTERNAL LAB: This is by far the most reliable and accurate method of the three. The difference between ATP and the Conventional Microbiology is 30-40%.

Other Common Issues Faced By Customers

- QC Fail—microbiology control, customer reject

- CIP Efficiency—Time

- Utility Savings—Water, Energy

- Elastomer Failure

- Know-How to Clean

- Hidden Areas & Dead Legs

- Microbiology Validation Method

- Choice of Solutions

- Temperature, time, and concentrations

Ensuring HACCP Compliance with ORAPI's CIP Solutions

HACCP (Hazard Analysis and Critical Control Points) is a comprehensive approach to identifying, assessing, and managing food safety risks. Achieving HACCP compliance in Cleaning in Place (CIP) systems may seem like a daunting task, but with the assistance of ORAPI experts, you can meet the criteria with ease by utilising our products and aftercare services.

Food contamination is a persistent hazard in food processing facilities, but ORAPI’s powerful cleaning solutions such as SPECTRUM, TRANSFORM PLUS, ACID PEROXAPHOS, and DESTINY can thoroughly clean every nook and cranny of the equipment, preventing contamination from food and beverage remnants, product residues, and biofilms.

As a solution provider, ORAPI experts can help you establish critical control points, including dead legs, where hazards can be controlled or prevented. We can assist you in determining the best approach to managing hazards in these points, in addition to establishing procedures to regularly monitor and verify that Critical Control Points (CCPs) are operating within scientifically established limits.

If monitoring indicates that a CCP is not functioning within its critical limits, we will take corrective action by helping you verify your CIP procedures with the appropriate validation methods mentioned above.

Conclusion

In conclusion, ORAPI Solutions provides high-quality cleaning solutions for the food industry, which are essential in ensuring the cleanliness and safety of manufacturing equipment. These solutions include SPECTRUM 5923, ACID PERAXOPHOS 2681, and SANITISER DESTINY 3300, which are effective in removing inorganic deposits and sanitising food contact surfaces. The Sinner Circle is the cornerstone of successful cleaning, and it involves balancing the right chemical, temperature, time, and action. The CIP cleaning cycle consists of 5 fundamental steps, including pre-rinse, washing with caustic, acid wash, application of sanitizer, and a thorough rinse, and it is crucial to use potable water instead of tap water in the CIP process. By using appropriate chemical solutions, food industry operators can prevent the formation of pitts, rust, and other potential risks to the equipment, ensuring compliance with regulations and maintaining the quality of food and beverages.